Efficiency and Longevity: The Promise of Copper Coated Steel Wire

Release Time:

Nov 14,2025

Efficiency and Longevity: The Promise of Copper Coated Steel Wire Introduction to Copper Coated Steel Wire Copper coated steel wire represents a significant advancement in the field of construction and decorative materials. The combination of steel's strength and copper's excellent electrical and thermal conductivity creates a versatile product that excels in various applications. This article aim

Efficiency and Longevity: The Promise of Copper Coated Steel Wire

Introduction to Copper Coated Steel Wire

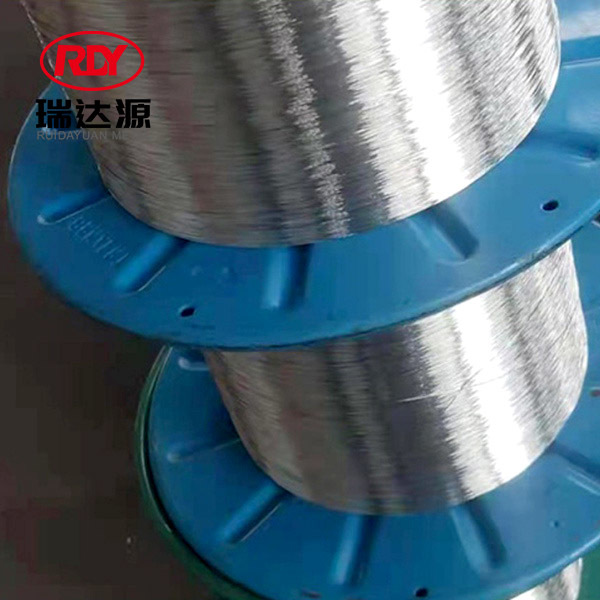

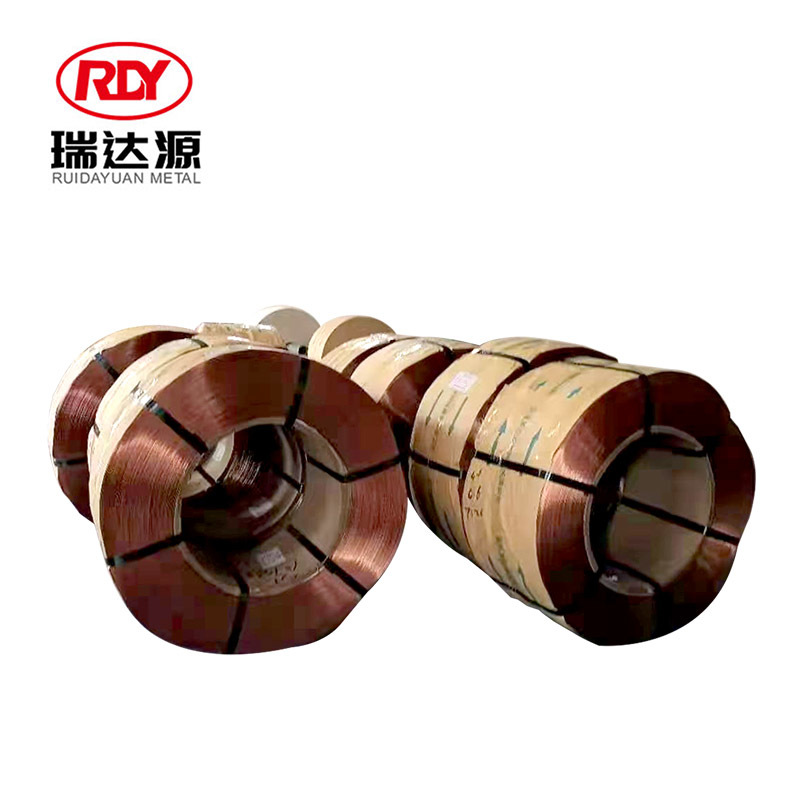

Copper coated steel wire represents a significant advancement in the field of construction and decorative materials. The combination of steel's strength and copper's excellent electrical and thermal conductivity creates a versatile product that excels in various applications. This article aims to explore the efficiency and longevity of copper coated steel wire, focusing on its benefits, uses, and future potential.

The Composition of Copper Coated Steel Wire

Understanding the Material Structure

Copper coated steel wire consists of a core made of high-strength steel, which is then coated with a layer of copper. This unique composition provides the wire with enhanced properties that are not achievable with either material alone.

Benefits of the Composite Material

The copper coating offers several advantages, including:

1. **Corrosion Resistance**: The copper layer protects the steel from rust and degradation, extending the wire's lifespan.

2. **Conductivity**: Copper is an excellent conductor of electricity, making this wire ideal for electrical applications.

3. **Aesthetic Appeal**: The copper finish provides a visually attractive appearance, suitable for decorative uses.

Applications of Copper Coated Steel Wire

Construction and Engineering

Copper coated steel wire is widely used in construction projects due to its durability and strength. Its applications include:

- **Reinforcement**: Used as a reinforcement material in concrete structures, providing additional stability.

- **Wiring**: Ideal for electrical wiring where conductivity is essential.

Decorative Uses

The aesthetic properties of copper coated steel wire make it a popular choice for decorative applications, such as:

- **Fencing**: Used in ornamental fencing, offering both security and style.

- **Art Installations**: Favored by artists for its unique color and malleability.

Performance Features of Copper Coated Steel Wire

Durability and Longevity

Durability is a critical factor in construction materials. Copper coated steel wire boasts a long lifespan due to its resistance to environmental factors that commonly affect other types of wire. The protective copper layer significantly reduces the risk of corrosion and wear.

Efficiency in Usage

When it comes to efficiency, copper coated steel wire outperforms traditional steel wire in several ways:

- **Reduced Maintenance Costs**: The longevity of this material leads to lower maintenance and replacement costs over time.

- **Better Performance in Electrical Applications**: The conductivity of copper allows for more efficient energy transmission, reducing energy loss.

Environmental Impact and Sustainability

Recyclability of Copper Coated Steel Wire

One of the most significant advantages of copper coated steel wire is its recyclability. Both steel and copper are highly recyclable materials. As sustainability becomes increasingly important to the construction industry, using recyclable materials can significantly reduce the overall environmental impact.

Energy Efficiency in Production

The manufacturing process of copper coated steel wire has evolved to be more energy-efficient. New technologies and methods reduce the amount of energy consumed during production while maintaining high-quality standards.

Future Prospects of Copper Coated Steel Wire

Innovations and Technological Advances

With ongoing research and development, the future of copper coated steel wire looks promising. Innovations in coatings and material science may further enhance its properties, making it even more versatile for future applications.

Market Demand and Trends

As the construction industry continues to grow, the demand for durable, efficient materials like copper coated steel wire is expected to rise. Trends towards sustainable and eco-friendly building practices will further bolster the market for this innovative wire.

FAQs About Copper Coated Steel Wire

1. What are the main benefits of copper coated steel wire?

Copper coated steel wire offers enhanced corrosion resistance, electrical conductivity, and aesthetic appeal, making it an ideal choice for various applications.

2. Can copper coated steel wire be used in outdoor applications?

Yes, its corrosion-resistant properties make it suitable for outdoor use, including fencing and construction.

3. Is copper coated steel wire more expensive than regular steel wire?

While the initial cost may be higher, the reduced maintenance and longer lifespan of copper coated steel wire often result in overall cost savings.

4. How does the coating process work?

The steel wire is coated with copper through methods such as electroplating, ensuring a uniform and durable layer.

5. What industries use copper coated steel wire?

It is widely used in construction, electrical wiring, and decorative applications, among others.

Conclusion

In summary, copper coated steel wire stands out as a superior choice in the realm of construction and decorative materials. Its unique combination of the strength of steel and the conductivity of copper provides unmatched efficiency and longevity. As we look towards the future, the continuous advancements in material science promise to further enhance its properties, making it an increasingly valuable asset in various industries. By choosing copper coated steel wire, we invest in a durable, efficient, and sustainable solution that meets the demands of modern construction and design.

Keywords:

Related news