Understanding Galvanized Spring Steel Wire: Essential Insights for the Construction Industry

Release Time:

Nov 07,2025

Galvanized spring steel wire is a specialized product known for its durability and resistance to corrosion, making it an ideal choice for various applications in the construction and decorative materials industry. The galvanization process involves coating the steel wire with a layer of zinc, which significantly enhances its resistance to environmental factors and extends its lifespan. This unique

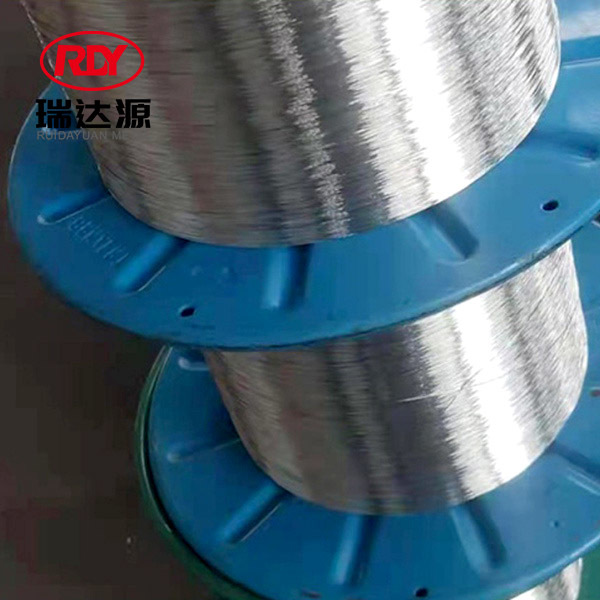

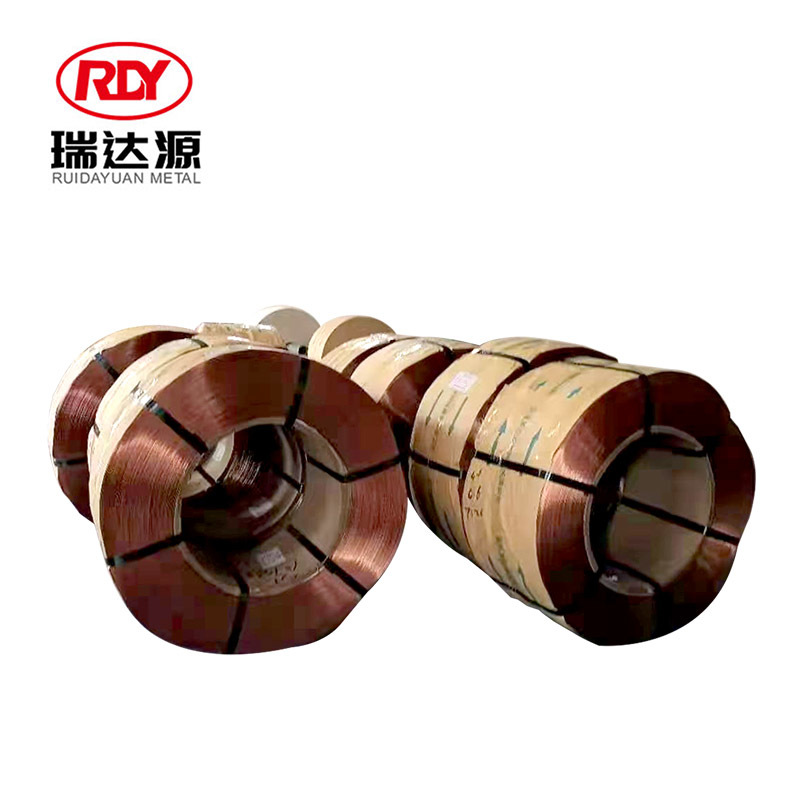

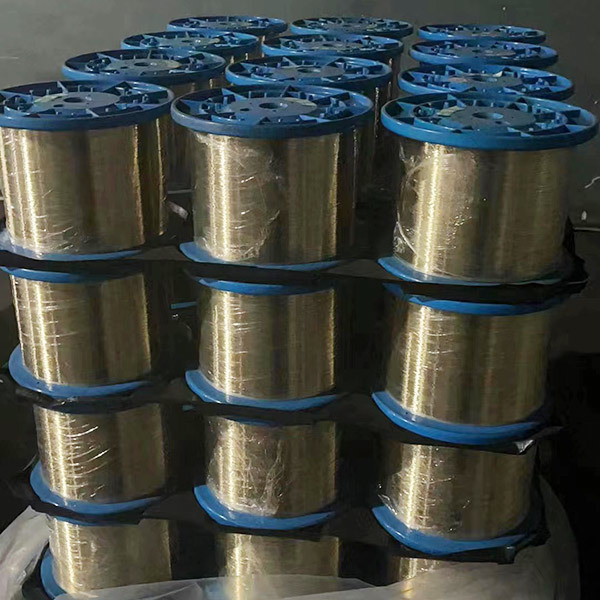

Galvanized spring steel wire is a specialized product known for its durability and resistance to corrosion, making it an ideal choice for various applications in the construction and decorative materials industry. The galvanization process involves coating the steel wire with a layer of zinc, which significantly enhances its resistance to environmental factors and extends its lifespan. This unique property is particularly beneficial in construction where materials are often exposed to harsh conditions.

One of the primary advantages of galvanized spring steel wire is its high tensile strength. This strength is essential for applications that require materials to withstand heavy loads and stresses. In the context of building construction, this wire is often utilized in reinforcing structures, such as in tension cables or supports. Its ability to return to its original shape after deformation makes it an excellent choice for springs and various fastening applications, ensuring that structures remain stable and secure over time.

Furthermore, galvanized spring steel wire offers excellent fatigue resistance. This characteristic is crucial when the wire is subjected to cyclic loading, which can happen in various construction scenarios. For example, in bridges or large commercial buildings, using this type of wire can help improve the overall safety and longevity of the structure by minimizing the risk of material failure.

In terms of application, galvanized spring steel wire can be readily used in a variety of construction projects. It is commonly found in the manufacturing of spring mechanisms, fencing, and even in the automotive industry for certain structural components. The versatility of this wire allows it to adapt to different functions, making it a go-to option among builders and manufacturers alike.

Another practical benefit of galvanized spring steel wire is its low maintenance requirement. The zinc coating protects the steel from moisture and other corrosive agents, reducing the need for frequent inspections and replacements. This feature not only saves time but also cuts down on costs associated with maintenance and repairs, making it a smart investment for any construction project.

In conclusion, galvanized spring steel wire is an indispensable material in the construction and decorative sectors. Its corrosion resistance, high tensile strength, fatigue resistance, and low maintenance needs make it a reliable choice for various applications. Understanding these aspects can help professionals make informed decisions when selecting materials for their projects, ultimately contributing to safer and more durable structures.

One of the primary advantages of galvanized spring steel wire is its high tensile strength. This strength is essential for applications that require materials to withstand heavy loads and stresses. In the context of building construction, this wire is often utilized in reinforcing structures, such as in tension cables or supports. Its ability to return to its original shape after deformation makes it an excellent choice for springs and various fastening applications, ensuring that structures remain stable and secure over time.

Furthermore, galvanized spring steel wire offers excellent fatigue resistance. This characteristic is crucial when the wire is subjected to cyclic loading, which can happen in various construction scenarios. For example, in bridges or large commercial buildings, using this type of wire can help improve the overall safety and longevity of the structure by minimizing the risk of material failure.

In terms of application, galvanized spring steel wire can be readily used in a variety of construction projects. It is commonly found in the manufacturing of spring mechanisms, fencing, and even in the automotive industry for certain structural components. The versatility of this wire allows it to adapt to different functions, making it a go-to option among builders and manufacturers alike.

Another practical benefit of galvanized spring steel wire is its low maintenance requirement. The zinc coating protects the steel from moisture and other corrosive agents, reducing the need for frequent inspections and replacements. This feature not only saves time but also cuts down on costs associated with maintenance and repairs, making it a smart investment for any construction project.

In conclusion, galvanized spring steel wire is an indispensable material in the construction and decorative sectors. Its corrosion resistance, high tensile strength, fatigue resistance, and low maintenance needs make it a reliable choice for various applications. Understanding these aspects can help professionals make informed decisions when selecting materials for their projects, ultimately contributing to safer and more durable structures.

Keywords:

Related news