Optimizing Strength and Flexibility with Steel Cord Solutions: A Comprehensive Guide

Release Time:

Oct 17,2025

Optimizing Strength and Flexibility with Steel Cord Solutions The construction and decorative materials industry has increasingly turned to innovative solutions that offer enhanced strength and flexibility. Among these, steel cord solutions have emerged as a game-changer. This article delves into the multifaceted benefits of steel cords, the technology behind them, and their applications in variou

Optimizing Strength and Flexibility with Steel Cord Solutions

The construction and decorative materials industry has increasingly turned to innovative solutions that offer enhanced strength and flexibility. Among these, steel cord solutions have emerged as a game-changer. This article delves into the multifaceted benefits of steel cords, the technology behind them, and their applications in various sectors. We aim to provide a thorough understanding of how optimizing these characteristics can benefit both manufacturers and end-users.

Understanding Steel Cord Solutions

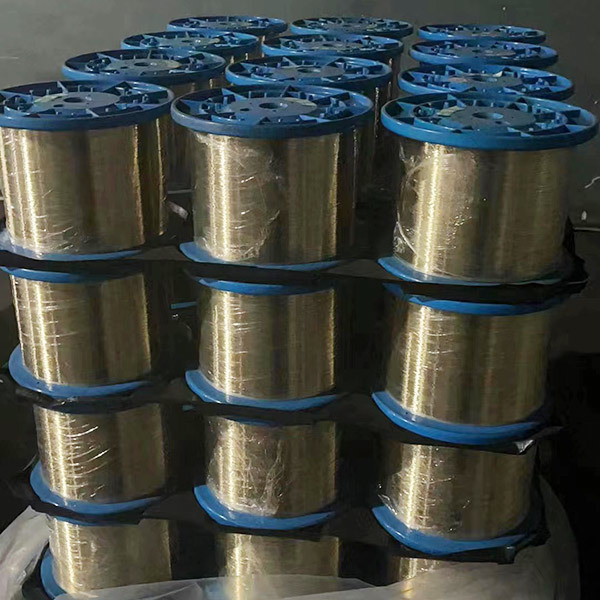

Steel cords are essentially strands of steel wire woven together to create a robust and flexible material. They are widely recognized for their high tensile strength and superior elasticity, making them ideal for applications in **automotive**, **construction**, and **industrial** sectors. Their unique properties allow for a perfect balance between strength and flexibility, which is crucial in many applications.

The Composition of Steel Cords

Typically composed of high-carbon steel, steel cords undergo extensive treatments to enhance their mechanical properties. The combination of different materials and wrapping techniques contributes to their performance under various stress conditions. They can range in diameter from 0.1 mm to several millimeters, allowing customization based on specific requirements.

Types of Steel Cords

- Single Wire Cords: These are straightforward steel wires offering basic flexibility and strength.

- Twisted Steel Cords: Manufactured by twisting several wires together, these cords offer enhanced tensile strength.

- Multistrand Cords: Consisting of multiple twisted strands, these provide excellent flexibility and durability.

The Importance of Strength in Steel Cords

One of the primary advantages of using steel cords is their unparalleled strength. This strength is critical in applications where high pressures and weights are involved. For instance, in the tire industry, steel cords enhance the durability and lifespan of tires, offering a safety benefit for vehicles on the road.

Applications of Strong Steel Cords

Steel cords are used extensively in a variety of applications, including:

- Tires: Providing structural integrity and longevity while enhancing performance.

- Belts: Used in industrial machinery to transfer power effectively while resisting wear and tear.

- Conveyor Systems: Essential for transporting heavy materials in manufacturing and logistics.

- Construction Materials: Reinforcing concrete structures to improve load-bearing capacity.

The Role of Flexibility in Steel Cords

While strength is vital, flexibility is equally important in many applications. The ability to bend without breaking allows steel cords to be used in intricate designs and movements. This flexibility is what makes steel cords indispensable in the automotive and construction industries.

Enhancing Flexibility Through Design

To optimize flexibility, manufacturers focus on innovative designs and materials. Techniques such as varying the twist pattern of the wires or incorporating additional materials can significantly enhance the flexibility of steel cords. These advancements make them suitable for applications requiring high adaptability.

Applications of Flexible Steel Cords

- Automotive Suspension Systems: Enhancing ride quality by absorbing shocks while maintaining structural integrity.

- Flexible Hoses: Used in hydraulic and pneumatic applications where adaptability is required.

- Textiles: Incorporated in fabrics for increased durability and resistance to wear.

Technological Innovations in Steel Cord Production

Advancements in technology have led to the development of cutting-edge steel cord manufacturing techniques. These innovations not only improve the quality of the cords but also reduce production costs and environmental impact.

New Manufacturing Techniques

Several manufacturing processes have emerged, including:

- Cold Drawing: This technique enhances tensile strength by reducing the diameter of the wire while ensuring uniformity.

- Heat Treatment: Applying heat processes increases hardness and flexibility, making cords more resilient.

Environmental Considerations

As sustainability becomes a focus in manufacturing, steel cord producers are exploring ways to reduce waste and energy consumption. Using recycled materials and adopting eco-friendly practices can significantly lessen their environmental footprint.

Benefits of Using Steel Cord Solutions

The utilization of steel cord solutions presents a myriad of benefits. Key advantages include:

- Increased Durability: Steel cords significantly enhance the lifespan of products, especially in high-stress environments.

- Cost-Efficiency: By reducing the need for frequent replacements, steel cords offer long-term savings for manufacturers.

- Enhanced Safety: The superior strength of steel cords contributes to safer products, particularly in automotive and industrial applications.

The Future of Steel Cord Solutions

As industries continue to evolve, the demand for advanced steel cord solutions is expected to grow. Innovations in material science and production techniques will lead to even stronger and more flexible options. The integration of smart technology into steel cord applications may also pave the way for enhanced performance monitoring and maintenance.

Emerging Trends

Key trends that are likely to shape the future of steel cord solutions include:

- Smart Materials: The development of self-monitoring cords that can provide real-time feedback on performance.

- Sustainability: Growing emphasis on eco-friendly manufacturing processes and materials.

- Customization: Increased demand for tailored solutions to meet specific industry requirements.

Frequently Asked Questions (FAQs)

1. What are steel cords primarily used for?

Steel cords are commonly used in tire manufacturing, conveyor belts, and construction materials due to their strength and flexibility.

2. How does the manufacturing process affect the properties of steel cords?

The manufacturing process, including techniques like cold drawing and heat treatment, directly influences the strength, flexibility, and overall quality of steel cords.

3. Are there environmentally friendly options for steel cords?

Yes, many manufacturers are adopting sustainable practices, such as using recycled materials and minimizing energy consumption during production.

4. Can steel cords be customized for specific applications?

Absolutely! Steel cords can be tailored in terms of diameter, twist pattern, and coating to meet the unique requirements of various applications.

5. What is the future outlook for steel cord solutions?

The future looks promising, with advancements in material science, the integration of smart technology, and a focus on sustainability driving innovation in steel cord solutions.

Conclusion

Steel cord solutions represent a significant leap forward in achieving optimal strength and flexibility across various industries. By understanding their composition, applications, and future potential, we can harness their benefits for a wide range of uses. As technology continues to evolve, steel cords will undoubtedly play a pivotal role in enhancing product performance and longevity. Investing in these innovative solutions not only drives efficiency but also contributes to safer and more sustainable practices in construction and decoration materials.

Keywords:

Related news