The Golden Thread: Exploring the Versatility of Copper Coated Iron Wire

Release Time:

Oct 03,2025

The Golden Thread: Exploring the Versatility of Copper Coated Iron Wire In the world of construction and decorative materials, **copper coated iron wire** stands out as a remarkable innovation. This wire, characterized by its unique coating of copper over iron, offers a blend of durability, electrical conductivity, and aesthetic appeal. In this article, we will explore the multifaceted application

The Golden Thread: Exploring the Versatility of Copper Coated Iron Wire

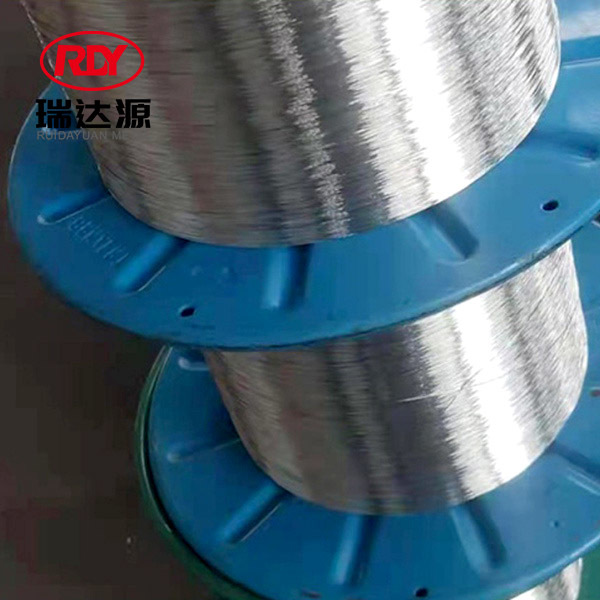

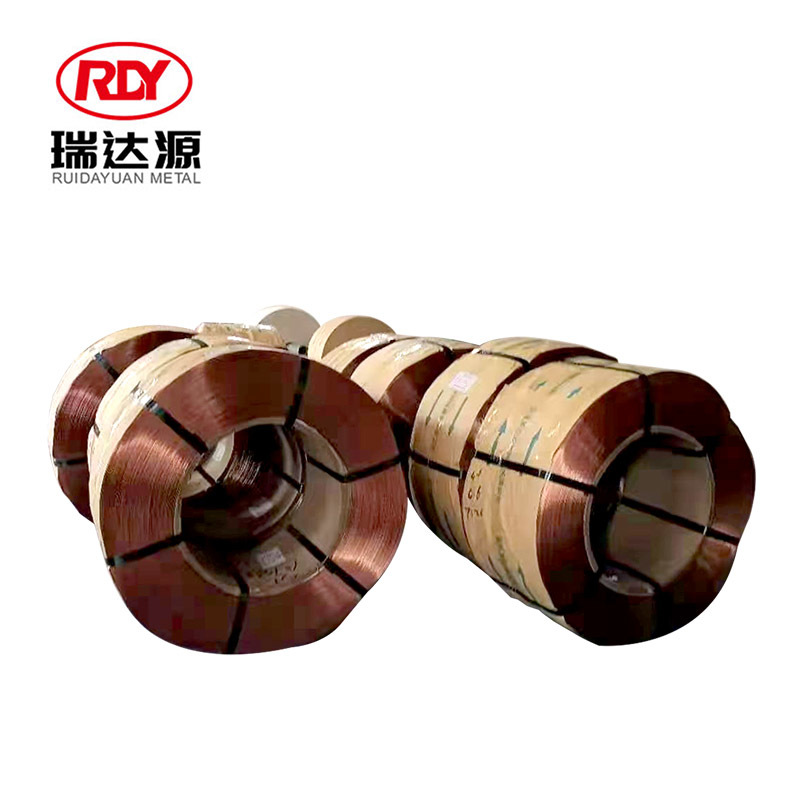

In the world of construction and decorative materials, **copper coated iron wire** stands out as a remarkable innovation. This wire, characterized by its unique coating of copper over iron, offers a blend of durability, electrical conductivity, and aesthetic appeal. In this article, we will explore the multifaceted applications and advantages of copper coated iron wire, its properties, and why it is becoming a preferred choice in various industries.

Table of Contents

- 1. Introduction to Copper Coated Iron Wire

- 2. Unique Properties of Copper Coated Iron Wire

- 3. Applications of Copper Coated Iron Wire

- 3.1 In Construction: The Backbone of Strength

- 3.2 In Decorative Arts: Aesthetic Versatility

- 3.3 In Electrical Applications: Conductivity and Safety

- 4. The Benefits of Using Copper Coated Iron Wire

- 5. Maintenance and Care for Copper Coated Iron Wire

- 6. The Future of Copper Coated Iron Wire in Industry

- 7. Conclusion: The Enduring Appeal of Copper Coated Iron Wire

- 8. FAQs about Copper Coated Iron Wire

1. Introduction to Copper Coated Iron Wire

Copper coated iron wire is a **superior alternative** to traditional iron wire, enhanced by a coating of copper that provides additional benefits. This innovative material is created through a process called electroplating, where a thin layer of copper is applied to iron wire. The result is a product that not only retains the strength of iron but also benefits from the excellent conductivity and corrosion resistance of copper. Understanding copper coated iron wire’s potential is essential for industries looking to improve quality and efficiency.

2. Unique Properties of Copper Coated Iron Wire

To appreciate the versatility of copper coated iron wire, we must first examine its essential properties. These characteristics make it a valuable asset in various applications:

2.1 Strength and Durability

The iron core provides **robust strength**, making the wire suitable for load-bearing applications, while the copper layer enhances its resistance to rust and wear, extending its lifespan significantly.

2.2 Electrical Conductivity

Copper is renowned for its **excellent electrical conductivity**. When used in wire form, it allows for efficient current transmission, making it ideal for electrical applications.

2.3 Corrosion Resistance

The copper coating acts as a barrier against elements that lead to corrosion, making it suitable for outdoor and industrial applications where exposure to moisture and pollutants is inevitable.

2.4 Aesthetic Appeal

With its shiny, reddish-brown appearance, copper coated iron wire possesses an **aesthetic quality** that is highly sought after in decorative projects.

3. Applications of Copper Coated Iron Wire

Copper coated iron wire finds its place in **various sectors**, each capitalizing on its unique properties. Here are some notable applications:

3.1 In Construction: The Backbone of Strength

In the construction industry, copper coated iron wire is utilized for various purposes such as:

- Reinforcement: Used in concrete construction for enhanced tensile strength.

- Binding: Ideal for tying rebar and formwork, ensuring structural integrity.

- Fencing: Provides a sturdy option for fencing materials, combining strength with durability.

3.2 In Decorative Arts: Aesthetic Versatility

The decorative arts sector exploits the visual appeal of copper coated iron wire in:

- Crafts: Used in jewelry making, sculptures, and home decor for artistic creations.

- Architectural Elements: Incorporated in railings, gates, and fixtures to add a touch of elegance.

3.3 In Electrical Applications: Conductivity and Safety

With its excellent conductivity, copper coated iron wire is essential in:

- Wiring: Commonly used for low-voltage wiring in lighting and electronics.

- Grounding: Effective in grounding applications, protecting against electrical surges.

4. The Benefits of Using Copper Coated Iron Wire

The advantages of incorporating copper coated iron wire into projects are manifold:

4.1 Cost-Effectiveness

While the initial investment may be higher than regular iron wire, the **long-term cost savings** due to reduced maintenance and replacement needs make it an economical choice.

4.2 Versatility across Industries

The adaptability of copper coated iron wire allows it to be used across various industries, from construction to electronics, providing solutions tailored to specific needs.

4.3 Improved Safety Standards

As a result of its conductivity and corrosion resistance, using copper coated iron wire ensures higher safety standards in electrical applications, reducing the risk of accidents.

4.4 Eco-Friendly Options

The longevity and durability of copper coated iron wire contribute to a **more sustainable** lifecycle, reducing waste and environmental impact.

5. Maintenance and Care for Copper Coated Iron Wire

To maximize the lifespan of copper coated iron wire, proper maintenance is necessary:

5.1 Regular Inspection

Frequent checks for signs of wear or corrosion can prevent future issues. Catching problems early is key to maintaining functionality.

5.2 Cleaning

Keep the wire clean from dirt and debris to avoid any deterioration. Mild soap and water can effectively remove buildup without damaging the wire.

5.3 Proper Storage

When not in use, store copper coated iron wire in a dry, cool place to avoid moisture exposure and subsequent corrosion.

6. The Future of Copper Coated Iron Wire in Industry

As industries continue to innovate and demand materials that meet higher standards of performance, copper coated iron wire is poised for growth. Future trends may include:

6.1 Innovations in Coating Technologies

Developments in coating technologies could enhance the properties of copper coated iron wire further, increasing its applications.

6.2 Sustainable Manufacturing Practices

With a shift towards eco-friendliness, manufacturers may adopt sustainable practices in producing copper coated iron wire, resulting in a greener product.

7. Conclusion: The Enduring Appeal of Copper Coated Iron Wire

Copper coated iron wire embodies a blend of **strength**, **aesthetics**, and **versatility** that appeals to a wide range of industries. Its unique properties enable it to stand out as a preferred material for both practical and decorative applications. As we move forward, the continued evolution of this material promises exciting possibilities and innovations. Investing in copper coated iron wire is not just a choice for today; it is a commitment to quality and performance for the future.

8. FAQs about Copper Coated Iron Wire

8.1 What is copper coated iron wire made of?

Copper coated iron wire consists of a core of iron coated with a thin layer of copper, which enhances its properties.

8.2 What are the primary benefits of copper coated iron wire?

Key benefits include excellent strength, corrosion resistance, electrical conductivity, and aesthetic appeal.

8.3 Can copper coated iron wire be used indoors and outdoors?

Yes, its corrosion resistance makes it suitable for both indoor and outdoor applications.

8.4 How can I clean copper coated iron wire?

Use mild soap and water, avoiding harsh chemicals that may damage the copper coating.

8.5 Is copper coated iron wire recyclable?

Yes, it is recyclable, contributing to sustainable practices in material usage.

Keywords:

Related news