Galvanized Steel Wire: The Essential Element for Reliable Steel Rope Solutions

Release Time:

Oct 31,2025

Introduction to Galvanized Steel Wire Galvanized steel wire is renowned for its remarkable strength and resilience, making it a fundamental component in the manufacturing of reliable steel rope solutions. This highly durable material is coated with a layer of zinc, which not only enhances its resistance to corrosion but also significantly extends its lifespan. In this article, we will explore the

Introduction to Galvanized Steel Wire

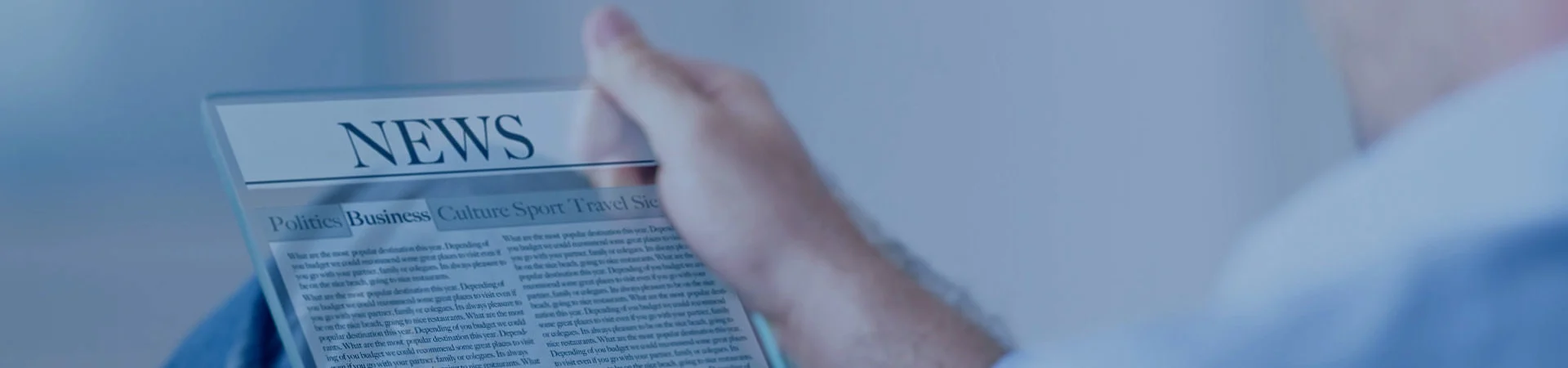

Galvanized steel wire is renowned for its remarkable strength and resilience, making it a fundamental component in the manufacturing of reliable steel rope solutions. This highly durable material is coated with a layer of zinc, which not only enhances its resistance to corrosion but also significantly extends its lifespan. In this article, we will explore the various aspects of galvanized steel wire, its applications, benefits, and why it is a preferred choice in numerous industries.

Understanding Galvanization

What is Galvanization?

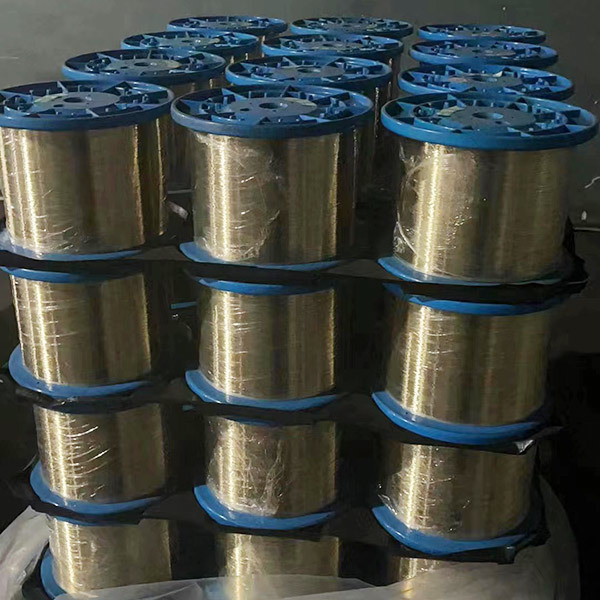

Galvanization is a process where steel is coated with a thin layer of zinc to protect it from corrosion. This protective layer acts as a barrier, preventing moisture and oxygen from reaching the steel surface. The galvanization process involves several methods, including hot-dip galvanizing and electro-galvanizing, which can significantly enhance the steel wire’s durability.

How Galvanized Steel Wire is Made

The production of galvanized steel wire begins with the careful selection of high-quality steel. The wire is then drawn through a series of dies to achieve the desired diameter. After the wire is formed, it undergoes the galvanization process, where it is immersed in molten zinc, resulting in a strong bond between the zinc and the steel surface. This process not only provides a protective layer but also improves the wire's tensile strength.

The Properties of Galvanized Steel Wire

Corrosion Resistance

One of the most significant advantages of galvanized steel wire is its exceptional corrosion resistance. The zinc coating effectively protects the underlying steel from rust and degradation, making it ideal for outdoor and marine applications where exposure to moisture is prevalent.

High Tensile Strength

Galvanized steel wire boasts impressive tensile strength, which is crucial for applications requiring substantial load-bearing capabilities. This strength makes it suitable for use in a variety of industries, including construction, agriculture, and transportation.

Flexibility and Ductility

In addition to its strength, galvanized steel wire is also highly flexible, allowing it to be bent and twisted without compromising its structural integrity. This ductility enables it to be woven into intricate designs, an essential characteristic for the production of steel ropes.

Applications of Galvanized Steel Wire

Construction Industry

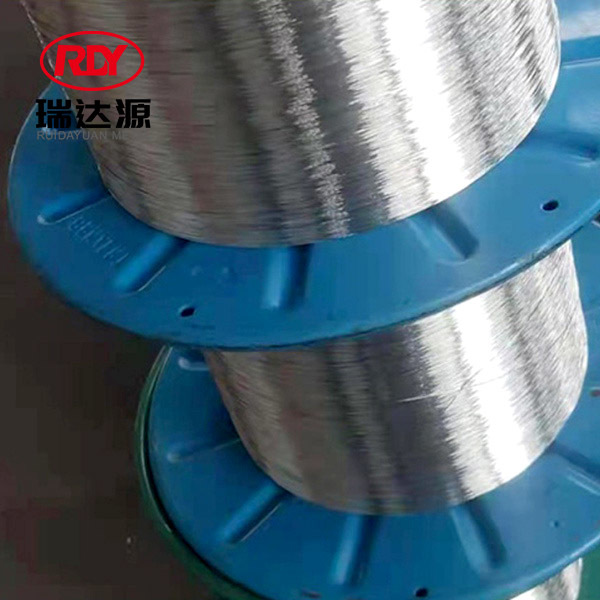

In the construction industry, galvanized steel wire is widely used for reinforcing concrete, supporting structures, and creating tension cables. Its strength and durability ensure that buildings and infrastructures can withstand various environmental pressures.

Agricultural Uses

Farmers and agricultural businesses utilize galvanized steel wire for fencing, trellising, and securing crops. Its resistance to rust ensures that these structures last longer, providing reliable support for livestock and crops alike.

Marine and Outdoor Applications

Due to its corrosion resistance, galvanized steel wire is ideal for marine applications. It is commonly used in the construction of docks, moorings, and other structures exposed to saltwater, ensuring longevity and reliability.

Industrial Equipment and Machinery

Galvanized steel wire is also prevalent in the manufacturing of industrial equipment and machinery. It is used in the production of cables, ropes, and various hardware components, providing the necessary strength and durability for demanding environments.

Benefits of Using Galvanized Steel Wire

Long Lifespan

The primary benefit of galvanized steel wire is its extended lifespan. The zinc coating significantly slows down the rate of corrosion, allowing the wire to maintain its structural integrity even in harsh conditions.

Cost-Effectiveness

Investing in galvanized steel wire can be economically advantageous. While the initial cost may be higher than non-galvanized alternatives, the reduced maintenance and replacement costs over time make it a cost-effective solution for various applications.

Environmental Benefits

Galvanized steel wire is also an environmentally friendly choice. The galvanization process does not emit harmful pollutants, and the wire itself is recyclable, reducing the overall environmental impact of its use.

Maintenance of Galvanized Steel Wire

Regular Inspections

To ensure the longevity of galvanized steel wire, regular inspections are essential. Check for any signs of wear, corrosion, or damage, especially in high-stress applications. Early detection can prevent costly replacements and ensure continued reliability.

Cleaning and Care

While galvanized steel wire is resistant to corrosion, it is still advisable to clean it periodically. Use a soft brush or cloth to remove any dirt or debris, and avoid harsh chemicals that may damage the zinc coating.

Storage Recommendations

Proper storage of galvanized steel wire is crucial for maintaining its quality. Store it in a dry, cool place to prevent moisture buildup, which could lead to corrosion over time.

Common Questions About Galvanized Steel Wire

1. What is the difference between hot-dip and electro-galvanized steel wire?

Hot-dip galvanizing involves immersing steel in molten zinc, creating a thicker and more durable coating. Electro-galvanizing uses an electrical process to apply a thinner layer of zinc. Hot-dip galvanized wire is generally more corrosion-resistant and suited for harsh environments.

2. Can galvanized steel wire be painted?

Yes, galvanized steel wire can be painted, although it is advisable to use a primer specifically designed for galvanized surfaces to ensure good adhesion.

3. Is galvanized steel wire suitable for heavy-duty applications?

Absolutely! Galvanized steel wire exhibits high tensile strength, making it an excellent choice for heavy-duty applications such as lifting, rigging, and construction.

4. How does the thickness of the zinc coating affect performance?

The thickness of the zinc coating directly impacts the wire's corrosion resistance. Thicker coatings provide better protection and are more suitable for harsh environments.

5. Where can I purchase high-quality galvanized steel wire?

You can find high-quality galvanized steel wire through specialized hardware stores, industrial suppliers, and online retailers. Always ensure you buy from reputable sources to guarantee product quality.

Conclusion

Galvanized steel wire serves as a foundational element in the production of reliable steel rope solutions. Its remarkable properties, including corrosion resistance, high tensile strength, and flexibility, make it indispensable across various industries. By investing in galvanized steel wire, businesses can benefit from its long lifespan and cost-effectiveness, ensuring they make a sustainable choice for their projects. Regular maintenance and proper care will further enhance the longevity and performance of galvanized steel wire, making it a smart investment for any application.

Keywords:

Related news