Maximizing Durability with Copper Coated Steel Wire Solutions

Release Time:

Apr 22,2025

Maximizing Durability with Copper Coated Steel Wire Solutions Introduction to Copper Coated Steel Wire Copper coated steel wire is rapidly becoming a preferred choice across various industries, thanks to its unique blend of durability and versatility. By combining the strength of steel with the corrosion resistance of copper, this innovative material offers a superior solution for applications r

Maximizing Durability with Copper Coated Steel Wire Solutions

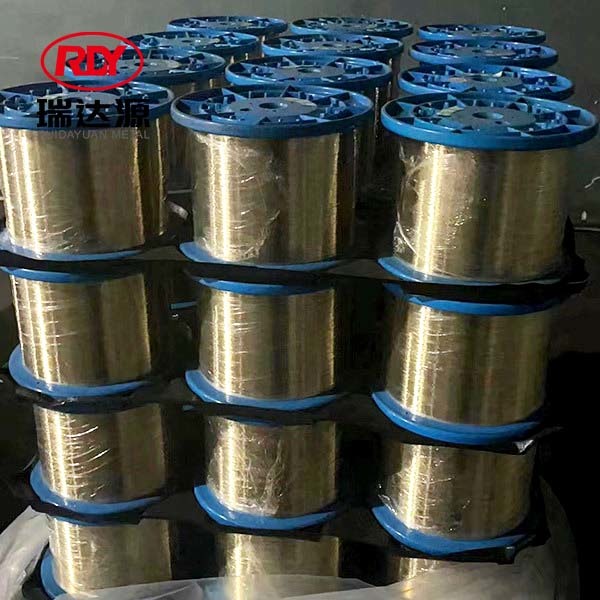

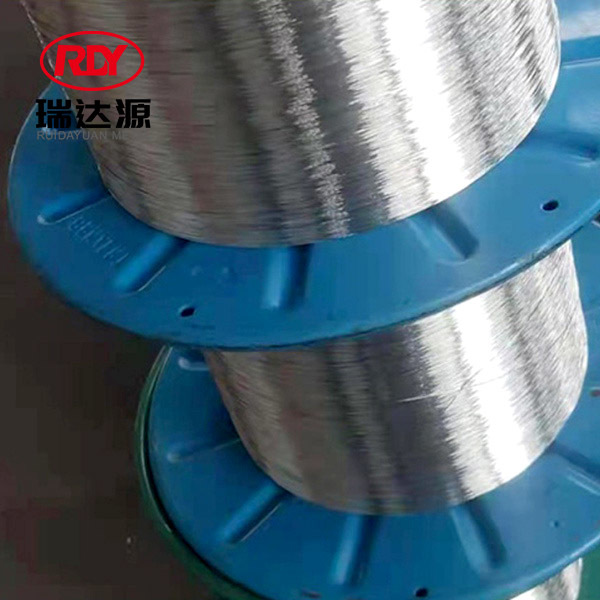

Introduction to Copper Coated Steel Wire

Copper coated steel wire is rapidly becoming a preferred choice across various industries, thanks to its unique blend of durability and versatility. By combining the strength of steel with the corrosion resistance of copper, this innovative material offers a superior solution for applications requiring high performance in challenging environments. In this article, we will delve into various aspects of copper coated steel wire, exploring its benefits, applications, maintenance practices, and much more.

The Benefits of Copper Coated Steel Wire

Enhanced Corrosion Resistance

One of the most significant advantages of copper coated steel wire is its **enhanced corrosion resistance**. The copper layer acts as a protective barrier, shielding the underlying steel from moisture and environmental factors that can lead to rust and degradation. This property is particularly crucial in industries such as construction, where exposure to the elements can significantly shorten the lifespan of materials.

Increased Strength and Durability

Copper coated steel wire maintains the tensile strength of steel while adding a layer of durability through its copper coating. This unique combination makes it suitable for heavy-duty applications, from fencing to cable manufacturing, ensuring that the wire can withstand high tensions without compromising its structural integrity.

Improved Electrical Conductivity

In applications where electrical conductivity is vital, copper coated steel wire excels. The copper coating enhances the wire's ability to conduct electricity, making it a preferred choice for electrical components and wiring systems. This feature opens up new possibilities for manufacturers seeking efficient solutions in electrical applications.

Cost-Effectiveness

While the initial investment for copper coated steel wire may be higher compared to traditional steel wire, the long-term benefits often outweigh the costs. With reduced maintenance needs and extended lifespan, businesses can save on replacement costs and labor over time. This makes copper coated steel wire a **cost-effective** solution for many industries.

Applications of Copper Coated Steel Wire

Construction Industry

In the construction industry, copper coated steel wire is used in various applications, including reinforcement for concrete and as part of cable systems. Its ability to withstand harsh environmental conditions makes it an ideal choice for outdoor structures, ensuring stability and safety.

Agricultural Fencing

Farming and agriculture also benefit from copper coated steel wire. Its corrosion resistance and durability make it a preferred material for fencing, keeping livestock secure while enduring exposure to weather elements. This ensures that farmers can maintain secure perimeters without frequent replacements.

Electrical and Communication Cables

In the realm of electrical engineering, copper coated steel wire is essential for high-performance communication cables. Its excellent conductivity ensures efficient data transmission, making it a staple in modern telecommunications infrastructure.

Industrial Applications

Industries relying on heavy machinery and equipment utilize copper coated steel wire for its durability and strength. It is commonly found in conveyor systems, lifting gear, and other applications that require robust wire solutions to handle significant loads.

Choosing the Right Copper Coated Steel Wire

Understanding Wire Specifications

When selecting copper coated steel wire, understanding specifications such as diameter, tensile strength, and coating thickness is crucial. These factors determine the wire's suitability for specific applications and its overall performance.

Assessing Environmental Conditions

Evaluating the environmental conditions where the wire will be used is essential. High humidity, saltwater exposure, and extreme temperatures can impact the wire's performance. Choosing the appropriate coating and specifications can enhance its longevity in these conditions.

Consulting with Manufacturers

Engaging with manufacturers and suppliers can provide valuable insights into the best options available. They can offer guidance based on industry standards and specific application needs, ensuring the selection of the most suitable copper coated steel wire.

Maintenance Tips for Copper Coated Steel Wire

Regular Inspections

Conducting regular inspections of copper coated steel wire installations can help identify any signs of wear or damage early on. Look for signs of corrosion, wear, or mechanical damage to ensure that the wire remains in optimal condition.

Cleaning Techniques

To maintain the integrity of the copper coating, clean the wire periodically. Use mild detergents and soft brushes to remove built-up dirt or debris. This not only enhances its appearance but also reinforces its protective qualities.

Protective Coatings

Consider applying additional protective coatings or sealants if the wire is exposed to particularly harsh environments. These coatings can add an extra layer of protection against environmental elements, further extending the wire's lifespan.

Common Myths About Copper Coated Steel Wire

Myth 1: Copper Coated Steel Wire is Only for Electrical Use

While copper coated steel wire is renowned for its electrical conductivity, its applications extend far beyond electrical uses. It is highly effective in various industries, including construction and agriculture, due to its strength and durability.

Myth 2: Copper Coated Wire is More Expensive Without Benefits

While the initial cost may be higher, the long-term savings from reduced maintenance and longer lifespan make copper coated steel wire a wise investment. Its benefits far outweigh the upfront costs for many applications.

Myth 3: Copper Coating is Not Durable Enough

The copper coating is engineered to withstand various environmental stresses. Properly designed and manufactured copper coated steel wire is, in fact, highly durable and reliable for many demanding applications.

FAQs About Copper Coated Steel Wire

1. What is copper coated steel wire made of?

Copper coated steel wire consists of a core made from high-quality steel, which is then coated with a layer of copper. This combination provides enhanced strength and corrosion resistance.

2. How does copper coating improve wire performance?

The copper coating enhances the wire's corrosion resistance and electrical conductivity, making it suitable for a wide range of applications that require both strength and durability.

3. Can copper coated steel wire be used in marine applications?

Yes, copper coated steel wire is effective in marine applications due to its corrosion resistance. It can withstand exposure to saltwater environments, although additional protective measures may be beneficial.

4. How should copper coated steel wire be stored?

Store copper coated steel wire in a dry, cool place to prevent moisture accumulation. Avoid direct exposure to elements that may lead to corrosion.

5. Is copper coated steel wire recyclable?

Yes, copper coated steel wire is recyclable. The materials can be processed and reused, making it an environmentally friendly option in addition to its performance benefits.

Conclusion

In conclusion, copper coated steel wire offers exceptional durability, corrosion resistance, and strength, making it a versatile choice for various applications across multiple industries. Understanding its benefits, applications, and maintenance can help businesses maximize their investment in this innovative material. By choosing the right specifications and engaging with knowledgeable manufacturers, you can ensure optimal performance and longevity in your copper coated steel wire solutions, ultimately enhancing the resilience of your projects.

Keywords:

Related news