Enhancing Structural Integrity with Galvanized Steel Wire Innovations

Release Time:

Apr 10,2025

Enhancing Structural Integrity with Galvanized Steel Wire Innovations Table of Contents 1. Introduction to Galvanized Steel Wire 2. The Importance of Structural Integrity in Construction 2.1 Defining Structural Integrity 2.2 The Role of Materials in Structural Integrity 3. What is Galvanization and Why It Matters 3.1 The Galvanization Process Explained 3.2 Advantages of Galvanized St

Enhancing Structural Integrity with Galvanized Steel Wire Innovations

Table of Contents

1. Introduction to Galvanized Steel Wire

2. The Importance of Structural Integrity in Construction

2.1 Defining Structural Integrity

2.2 The Role of Materials in Structural Integrity

3. What is Galvanization and Why It Matters

3.1 The Galvanization Process Explained

3.2 Advantages of Galvanized Steel Wire

4. Innovations in Galvanized Steel Wire Technologies

4.1 Advanced Coating Techniques

4.2 Smart Wire Technologies

5. Applications of Galvanized Steel Wire in Modern Construction

5.1 Reinforcement in Concrete Structures

5.2 Use in Structural Frameworks

6. Environmental Impact and Sustainability of Galvanized Steel Wire

7. Case Studies: Successful Implementation of Galvanized Steel Wire

8. FAQs about Galvanized Steel Wire and Structural Integrity

9. Conclusion

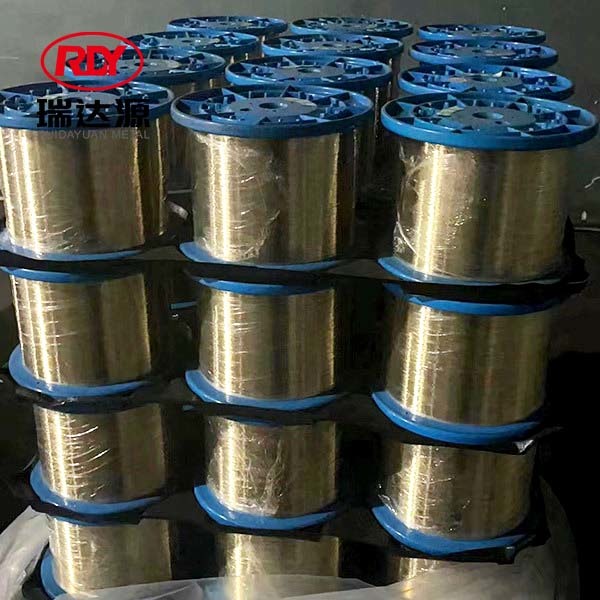

1. Introduction to Galvanized Steel Wire

Galvanized steel wire has become a cornerstone in the construction industry, known for its strength, versatility, and resistance to corrosion. As projects evolve and demands increase, the innovations within this realm continue to enhance the structural integrity of buildings and other constructions. In this article, we will explore the many facets of galvanized steel wire, its significance in maintaining structural integrity, and the innovations shaping its future.

2. The Importance of Structural Integrity in Construction

Understanding structural integrity is crucial for architects, engineers, and builders. It ensures the safety and durability of structures.

2.1 Defining Structural Integrity

Structural integrity refers to the ability of a structure to withstand its intended load without experiencing failure. In simpler terms, it means that a building can hold up under the weight it was designed to bear.

2.2 The Role of Materials in Structural Integrity

Materials play a pivotal role in achieving structural integrity. Steel, particularly galvanized steel wire, is favored for its strength-to-weight ratio and longevity, making it an essential component in various construction applications.

3. What is Galvanization and Why It Matters

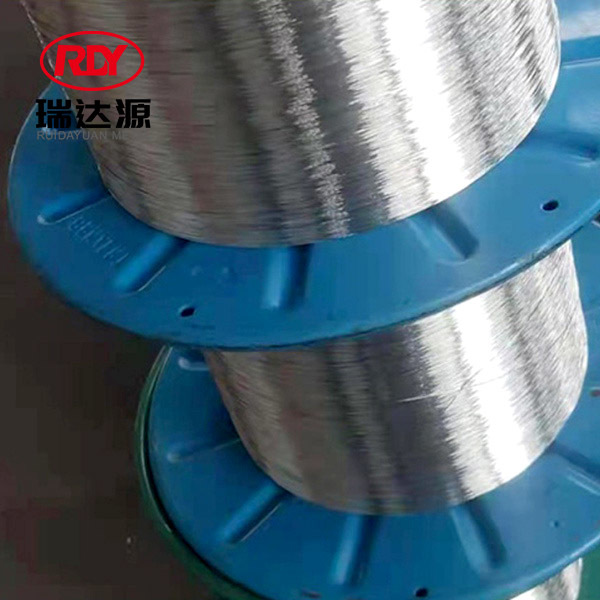

Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rusting. This technique significantly extends the lifespan of the material.

3.1 The Galvanization Process Explained

The most common method of galvanization is hot-dip galvanizing, where steel components are submerged in molten zinc. This results in a metallurgical bond that forms a durable and corrosion-resistant surface.

3.2 Advantages of Galvanized Steel Wire

The benefits of using galvanized steel wire are numerous. It provides enhanced resistance to corrosion, requires less maintenance, and can withstand harsh weather conditions. These qualities make it an ideal choice for structural applications.

4. Innovations in Galvanized Steel Wire Technologies

The advancements in galvanized steel wire technologies have led to improvements in performance and application versatility.

4.1 Advanced Coating Techniques

New coating technologies, including duplex systems that combine various materials for enhanced protection, have emerged. These innovations improve the longevity and durability of galvanized steel wire, making it even more resilient in challenging environments.

4.2 Smart Wire Technologies

Smart wire technologies are revolutionizing the use of galvanized steel wire. Incorporating sensors into the wire allows for real-time monitoring of structural health, offering insights into stress levels and potential weaknesses.

5. Applications of Galvanized Steel Wire in Modern Construction

Galvanized steel wire is widely used across various sectors in construction, significantly contributing to structural integrity.

5.1 Reinforcement in Concrete Structures

In concrete construction, galvanized steel wire is utilized for reinforcement. It provides the necessary tensile strength to concrete, which is inherently weak in tension. This combination ensures buildings can handle various loads and stresses.

5.2 Use in Structural Frameworks

Additionally, galvanized steel wire is employed in the structural frameworks of buildings, bridges, and other infrastructures. Its strength and durability make it suitable for supporting heavy loads while resisting environmental factors.

6. Environmental Impact and Sustainability of Galvanized Steel Wire

As the construction industry faces increasing scrutiny regarding environmental sustainability, galvanized steel wire stands out.

The production of galvanized steel is relatively energy-efficient, and the material is fully recyclable, contributing to a circular economy. These attributes align with modern building practices that prioritize sustainability and environmental responsibility.

7. Case Studies: Successful Implementation of Galvanized Steel Wire

Numerous projects have successfully utilized galvanized steel wire to enhance structural integrity.

For instance, the construction of a high-rise building in an earthquake-prone area showcased the effectiveness of galvanized steel wire reinforcement. The building withstood significant seismic activity, demonstrating the resilience and reliability of galvanized materials.

Another example includes the use of galvanized steel wire in bridge construction, where the wire's tensile strength prevented structural failure during heavy traffic loads.

8. FAQs about Galvanized Steel Wire and Structural Integrity

**Q1: What is the lifespan of galvanized steel wire?**

A1: Galvanized steel wire typically lasts for several decades, depending on the environmental conditions and maintenance.

**Q2: Can galvanized steel wire be used in marine environments?**

A2: Yes, galvanized steel wire is suitable for marine applications, particularly when using higher-grade coatings for enhanced corrosion resistance.

**Q3: Is galvanized steel wire easy to work with?**

A3: Absolutely! Galvanized steel wire is relatively easy to handle, cut, and shape, making it versatile for various applications.

**Q4: How does galvanized steel wire compare to other materials in terms of cost?**

A4: While galvanized steel wire may have a higher initial cost than some alternatives, its durability and low maintenance needs can result in lower long-term costs.

**Q5: Are there any health risks associated with galvanized steel wire?**

A5: There are no significant health risks when working with galvanized steel wire, provided standard safety practices are followed.

9. Conclusion

Galvanized steel wire represents a remarkable innovation in the construction industry, providing unmatched structural integrity and durability. As we continue to explore and implement new technologies and methods, the role of galvanized steel wire is bound to expand, ensuring safer, more resilient structures for future generations. Investing in galvanized steel wire is not just a choice for today; it’s a commitment to enduring quality and sustainability in construction.

Keywords:

Related news