Understanding Copper-Coated Steel Wire: A Versatile Material for Construction and Decoration

Release Time:

Mar 23,2025

Copper-coated steel wire is increasingly gaining traction in various applications within the construction and decoration materials sector. This unique material consists of a core of high-strength steel wire coated with a layer of copper, combining the beneficial properties of both metals. The result is a wire that not only provides exceptional tensile strength and durability but also enhances corr

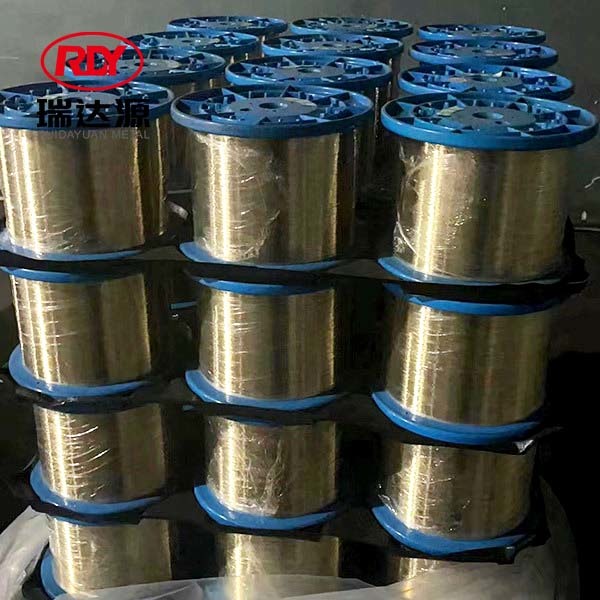

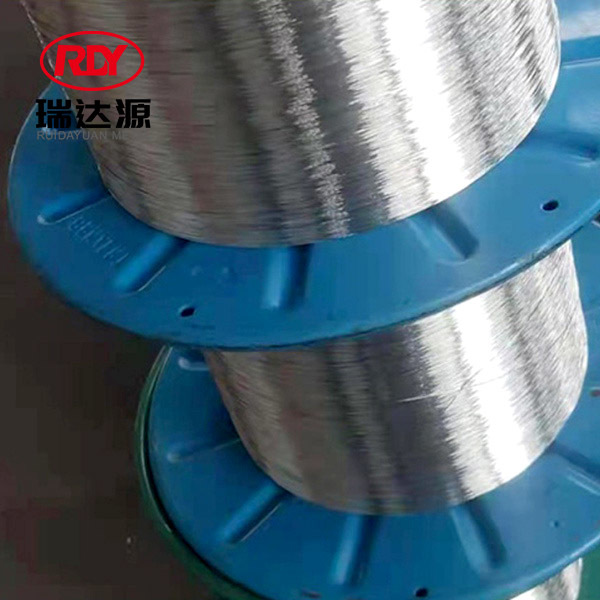

Copper-coated steel wire is increasingly gaining traction in various applications within the construction and decoration materials sector. This unique material consists of a core of high-strength steel wire coated with a layer of copper, combining the beneficial properties of both metals. The result is a wire that not only provides exceptional tensile strength and durability but also enhances corrosion resistance and electrical conductivity.

One of the primary advantages of copper-coated steel wire is its resistance to corrosion. The copper layer acts as a protective barrier that prevents the underlying steel from rusting, which is particularly beneficial in environments where moisture and chemical exposure are prevalent. This makes copper-coated steel wire an ideal choice for applications in coastal areas or regions with high humidity, where traditional steel wire might degrade quickly.

In addition to its corrosion resistance, copper-coated steel wire offers excellent electrical conductivity. This property is particularly valuable for applications that require grounding or bonding. For instance, in construction projects, ensuring proper grounding of electrical systems is crucial for safety, and copper-coated steel wire provides an effective solution. Its conductivity also makes it suitable for use in telecommunications, as it can facilitate signal transmission with minimal interference.

Another notable feature of copper-coated steel wire is its versatility in design and application. In architectural projects, this wire can be used for decorative purposes, enhancing the aesthetic appeal of structures while maintaining structural integrity. Its malleability allows it to be shaped into various forms, making it suitable for decorative fencing, railings, and artistic installations.

Furthermore, the combination of steel and copper in this wire creates a material that is not only strong but also lightweight. This characteristic simplifies handling and installation processes, reducing labor costs and time during construction. It can be easily integrated into various systems, whether for reinforcing concrete, creating wire mesh, or as part of a tensioning system in tensile structures.

When considering the use of copper-coated steel wire in your projects, it’s essential to assess the specific requirements of your application. Factors such as environmental conditions, load-bearing capacities, and aesthetic goals should guide your decision-making process. Collaborating with suppliers and manufacturers who specialize in this material can provide further insights and help optimize your selection for the best outcomes.

In conclusion, copper-coated steel wire stands out as a superior choice in the realm of construction and decorative materials. Its unique blend of strength, corrosion resistance, and electrical properties makes it a valuable asset for a wide range of applications, allowing professionals in the industry to achieve both functional and aesthetic objectives efficiently.

One of the primary advantages of copper-coated steel wire is its resistance to corrosion. The copper layer acts as a protective barrier that prevents the underlying steel from rusting, which is particularly beneficial in environments where moisture and chemical exposure are prevalent. This makes copper-coated steel wire an ideal choice for applications in coastal areas or regions with high humidity, where traditional steel wire might degrade quickly.

In addition to its corrosion resistance, copper-coated steel wire offers excellent electrical conductivity. This property is particularly valuable for applications that require grounding or bonding. For instance, in construction projects, ensuring proper grounding of electrical systems is crucial for safety, and copper-coated steel wire provides an effective solution. Its conductivity also makes it suitable for use in telecommunications, as it can facilitate signal transmission with minimal interference.

Another notable feature of copper-coated steel wire is its versatility in design and application. In architectural projects, this wire can be used for decorative purposes, enhancing the aesthetic appeal of structures while maintaining structural integrity. Its malleability allows it to be shaped into various forms, making it suitable for decorative fencing, railings, and artistic installations.

Furthermore, the combination of steel and copper in this wire creates a material that is not only strong but also lightweight. This characteristic simplifies handling and installation processes, reducing labor costs and time during construction. It can be easily integrated into various systems, whether for reinforcing concrete, creating wire mesh, or as part of a tensioning system in tensile structures.

When considering the use of copper-coated steel wire in your projects, it’s essential to assess the specific requirements of your application. Factors such as environmental conditions, load-bearing capacities, and aesthetic goals should guide your decision-making process. Collaborating with suppliers and manufacturers who specialize in this material can provide further insights and help optimize your selection for the best outcomes.

In conclusion, copper-coated steel wire stands out as a superior choice in the realm of construction and decorative materials. Its unique blend of strength, corrosion resistance, and electrical properties makes it a valuable asset for a wide range of applications, allowing professionals in the industry to achieve both functional and aesthetic objectives efficiently.

Keywords:

Related news