Understanding the Importance of Steel Wire Spools in Industrial Applications

Release Time:

Sep 21,2024

In the realm of industrial equipment and components, particularly within the bearing and linear bearing sector, the spool of steel wire has become an essential item. Steel wire serves a multitude of functions in various applications, from reinforcement and support structures to the creation of intricate components. Understanding the properties and uses of steel wire spools can significantly enhanc

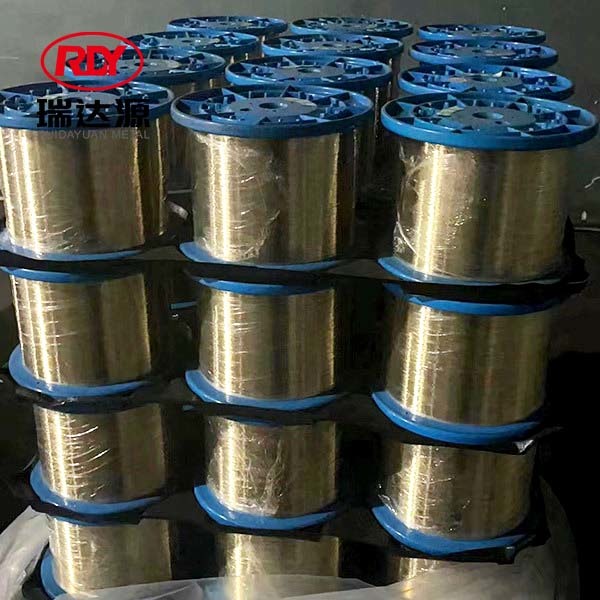

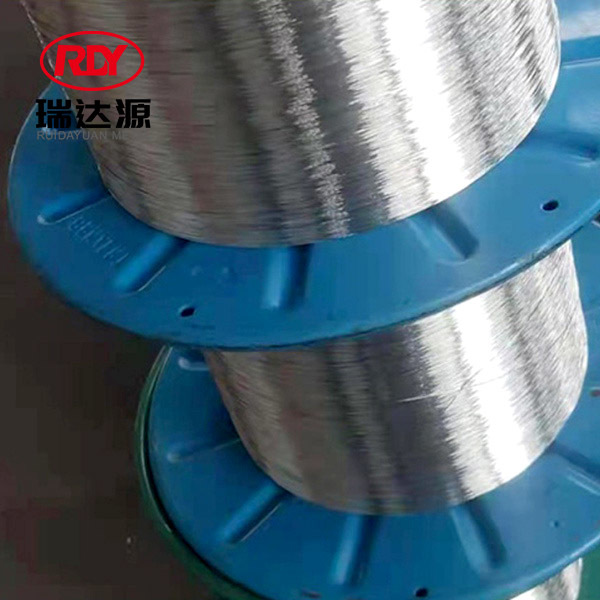

In the realm of industrial equipment and components, particularly within the bearing and linear bearing sector, the spool of steel wire has become an essential item. Steel wire serves a multitude of functions in various applications, from reinforcement and support structures to the creation of intricate components. Understanding the properties and uses of steel wire spools can significantly enhance operational efficiency and product quality.

One of the primary characteristics of steel wire is its strength and durability. Steel wire is known for its high tensile strength, which makes it ideal for applications where heavy loads are common. In linear bearing systems, steel wire can be utilized to create components that can withstand the rigors of movement and friction, ensuring smooth operation and longevity. The use of spooled steel wire allows for easier handling and storage, ultimately leading to reduced waste and increased productivity in manufacturing processes.

Moreover, steel wire spools come in various diameters and grades, catering to the specific needs of different applications. Understanding these specifications is crucial for selecting the right type of wire for your projects. For instance, finer gauges of steel wire are often used for more delicate applications, while thicker wires are necessary for heavy-duty tasks. This versatility is what makes steel wire spools invaluable in industrial settings.

Another significant advantage of using spooled steel wire is the ease of use it provides. When wire is wound onto spools, it can be fed into machines or tools with minimal fuss, reducing downtime and improving workflow efficiency. This is particularly important in environments where time is of the essence, and maintaining a steady flow of materials is crucial.

In addition to operational benefits, using quality steel wire can also enhance the overall performance of bearing systems. The right type of steel wire can reduce friction and wear, leading to longer service life and fewer maintenance requirements. This not only saves costs in the long run but also ensures that systems are operating at peak performance.

In conclusion, the spool of steel wire plays a crucial role in the industrial equipment and components sector, especially when it comes to bearings and linear bearings. By understanding the specifications, benefits, and applications of steel wire, businesses can make informed decisions that enhance productivity and efficiency. Investing in quality steel wire ultimately leads to improved product performance and operational success, solidifying its place as a key component in industrial applications.

One of the primary characteristics of steel wire is its strength and durability. Steel wire is known for its high tensile strength, which makes it ideal for applications where heavy loads are common. In linear bearing systems, steel wire can be utilized to create components that can withstand the rigors of movement and friction, ensuring smooth operation and longevity. The use of spooled steel wire allows for easier handling and storage, ultimately leading to reduced waste and increased productivity in manufacturing processes.

Moreover, steel wire spools come in various diameters and grades, catering to the specific needs of different applications. Understanding these specifications is crucial for selecting the right type of wire for your projects. For instance, finer gauges of steel wire are often used for more delicate applications, while thicker wires are necessary for heavy-duty tasks. This versatility is what makes steel wire spools invaluable in industrial settings.

Another significant advantage of using spooled steel wire is the ease of use it provides. When wire is wound onto spools, it can be fed into machines or tools with minimal fuss, reducing downtime and improving workflow efficiency. This is particularly important in environments where time is of the essence, and maintaining a steady flow of materials is crucial.

In addition to operational benefits, using quality steel wire can also enhance the overall performance of bearing systems. The right type of steel wire can reduce friction and wear, leading to longer service life and fewer maintenance requirements. This not only saves costs in the long run but also ensures that systems are operating at peak performance.

In conclusion, the spool of steel wire plays a crucial role in the industrial equipment and components sector, especially when it comes to bearings and linear bearings. By understanding the specifications, benefits, and applications of steel wire, businesses can make informed decisions that enhance productivity and efficiency. Investing in quality steel wire ultimately leads to improved product performance and operational success, solidifying its place as a key component in industrial applications.

Keywords:

Related news