Enhancing Construction Durability with Copper-Coated Steel Fiber

Release Time:

Sep 19,2024

In the construction and decorative materials sector, the choice of reinforcement materials significantly impacts the durability and structural integrity of concrete. Among these materials, copper-coated steel fibers have emerged as a noteworthy alternative, offering unique benefits that align with modern construction demands. These fibers not only serve to enhance the physical properties of concre

In the construction and decorative materials sector, the choice of reinforcement materials significantly impacts the durability and structural integrity of concrete. Among these materials, copper-coated steel fibers have emerged as a noteworthy alternative, offering unique benefits that align with modern construction demands. These fibers not only serve to enhance the physical properties of concrete but also provide a solution to common issues associated with traditional reinforcement methods.

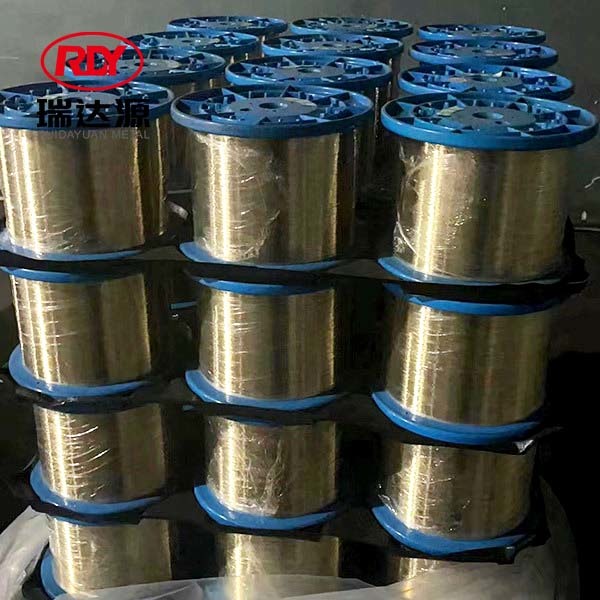

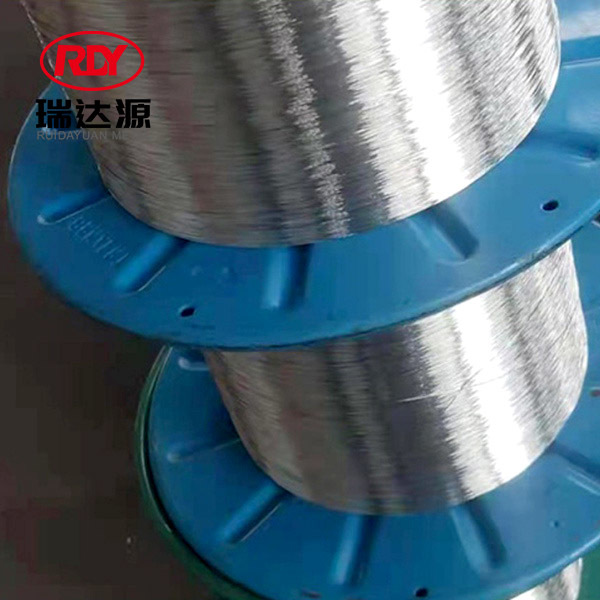

Copper-coated steel fibers consist of fine steel strands coated with a layer of copper. This coating serves multiple purposes, significantly improving the performance of the steel fibers in various applications. One of the primary benefits is enhanced corrosion resistance. Concrete structures are prone to deterioration due to environmental factors like moisture, chemicals, and temperature fluctuations. The copper coating helps mitigate the risk of rust formation, which is a common problem with traditional steel reinforcement. By utilizing copper-coated steel fibers, construction professionals can extend the lifespan of their structures, reducing maintenance costs and increasing reliability.

Additionally, the use of copper-coated steel fibers improves the mechanical properties of concrete. The fibers are known to enhance the tensile strength, flexural strength, and ductility of concrete mixtures. When integrated into the concrete matrix, these fibers provide better load distribution and crack resistance, making the resulting material more robust under stress. This is particularly advantageous in applications subjected to dynamic loads or extreme conditions, such as industrial floors, pavements, and precast products.

Another significant advantage is the ease of mixing and application. Copper-coated steel fibers can be seamlessly integrated into standard concrete mixes, allowing for flexibility in design and construction processes. This compatibility also means that construction teams can efficiently incorporate these fibers into existing projects without extensive modifications to their practices.

In terms of sustainability, using copper-coated steel fibers presents an eco-friendlier option compared to other reinforcement materials. As these fibers contribute to the overall longevity of structures, they help reduce the frequency of repairs and replacements, leading to less waste and lower resource consumption over time.

In conclusion, copper-coated steel fibers present a valuable enhancement to the construction and decorative materials industry. Their corrosion resistance, mechanical property improvements, ease of application, and sustainability make them a compelling choice for modern construction projects. As the industry continues to evolve, the adoption of innovative materials like copper-coated steel fibers will play a crucial role in shaping the future of durable and resilient construction practices.

Copper-coated steel fibers consist of fine steel strands coated with a layer of copper. This coating serves multiple purposes, significantly improving the performance of the steel fibers in various applications. One of the primary benefits is enhanced corrosion resistance. Concrete structures are prone to deterioration due to environmental factors like moisture, chemicals, and temperature fluctuations. The copper coating helps mitigate the risk of rust formation, which is a common problem with traditional steel reinforcement. By utilizing copper-coated steel fibers, construction professionals can extend the lifespan of their structures, reducing maintenance costs and increasing reliability.

Additionally, the use of copper-coated steel fibers improves the mechanical properties of concrete. The fibers are known to enhance the tensile strength, flexural strength, and ductility of concrete mixtures. When integrated into the concrete matrix, these fibers provide better load distribution and crack resistance, making the resulting material more robust under stress. This is particularly advantageous in applications subjected to dynamic loads or extreme conditions, such as industrial floors, pavements, and precast products.

Another significant advantage is the ease of mixing and application. Copper-coated steel fibers can be seamlessly integrated into standard concrete mixes, allowing for flexibility in design and construction processes. This compatibility also means that construction teams can efficiently incorporate these fibers into existing projects without extensive modifications to their practices.

In terms of sustainability, using copper-coated steel fibers presents an eco-friendlier option compared to other reinforcement materials. As these fibers contribute to the overall longevity of structures, they help reduce the frequency of repairs and replacements, leading to less waste and lower resource consumption over time.

In conclusion, copper-coated steel fibers present a valuable enhancement to the construction and decorative materials industry. Their corrosion resistance, mechanical property improvements, ease of application, and sustainability make them a compelling choice for modern construction projects. As the industry continues to evolve, the adoption of innovative materials like copper-coated steel fibers will play a crucial role in shaping the future of durable and resilient construction practices.

Keywords:

Related news