Wave Iron Wire: Redefining Structural Possibilities in Modern Construction

Release Time:

Sep 16,2024

Wave Iron Wire: Redefining Structural Possibilities in Modern Construction Table of Contents 1. Introduction to Wave Iron Wire 2. The Unique Properties of Wave Iron Wire 2.1 Strength and Durability 2.2 Flexibility and Adaptability 2.3 Aesthetic Appeal 3. Applications of Wave Iron Wire in Construction 3.1 Infrastructure Development 3.2 Residential Projects 3.3 Artistic Installations 4. Comparison w

Wave Iron Wire: Redefining Structural Possibilities in Modern Construction

Table of Contents

1. Introduction to Wave Iron Wire

2. The Unique Properties of Wave Iron Wire

2.1 Strength and Durability

2.2 Flexibility and Adaptability

2.3 Aesthetic Appeal

3. Applications of Wave Iron Wire in Construction

3.1 Infrastructure Development

3.2 Residential Projects

3.3 Artistic Installations

4. Comparison with Traditional Steel Materials

4.1 Cost-Effectiveness

4.2 Performance Analysis

5. The Manufacturing Process of Wave Iron Wire

5.1 Raw Material Selection

5.2 Production Techniques

6. Future Trends in Wave Iron Wire Usage

7. Frequently Asked Questions

8. Conclusion

1. Introduction to Wave Iron Wire

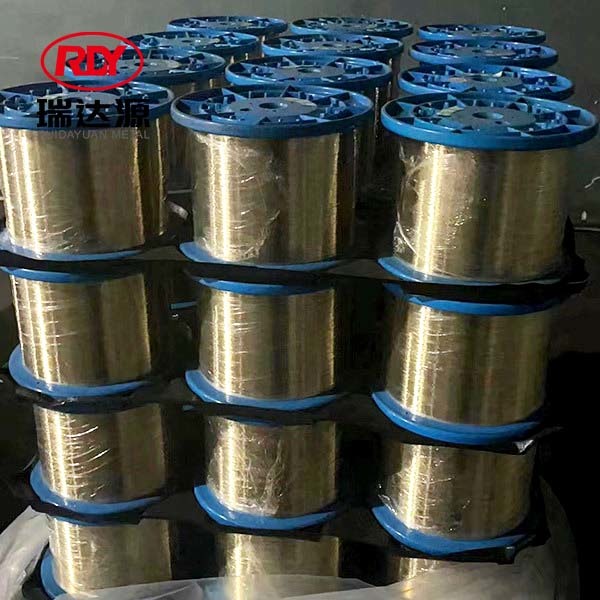

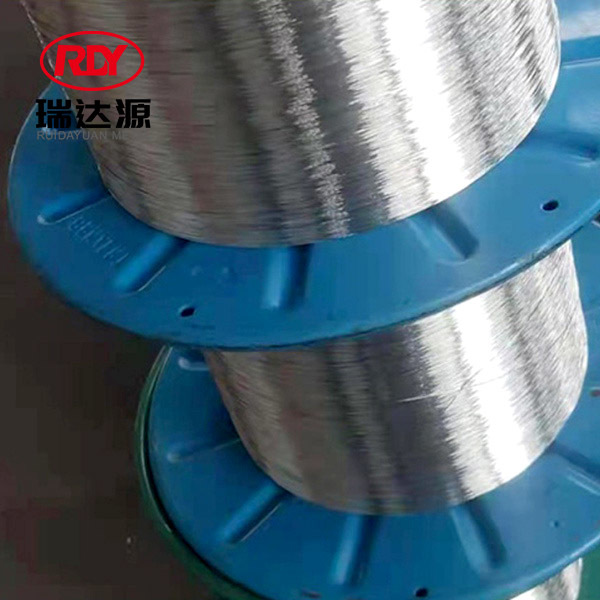

Wave iron wire is an innovative building material that has begun to redefine construction standards. Unlike traditional steel, wave iron wire features a unique, undulated design that enhances its structural properties while providing a distinctive aesthetic quality. This wire is increasingly being embraced by architects and builders due to its versatility and performance advantages.

2. The Unique Properties of Wave Iron Wire

Wave iron wire stands out in the landscape of construction materials. Its unique properties contribute significantly to its growing popularity.

2.1 Strength and Durability

One of the most remarkable attributes of wave iron wire is its exceptional strength. The wave patterns distribute stress evenly, making it less prone to breakage under heavy loads compared to conventional straight wire. This property is crucial in structural applications where safety and reliability are paramount.

2.2 Flexibility and Adaptability

Wave iron wire is not only strong but also incredibly flexible. This adaptability allows it to be molded into various shapes and sizes, making it suitable for a range of applications from reinforcement in concrete to intricate decorative elements in architecture.

2.3 Aesthetic Appeal

The undulating design of wave iron wire lends an artistic flair to structures. Architects are leveraging this material to create visually striking designs that stand out, enhancing the overall beauty of buildings and landscapes.

3. Applications of Wave Iron Wire in Construction

The versatility of wave iron wire opens up a multitude of applications across various sectors of construction.

3.1 Infrastructure Development

In infrastructure, wave iron wire is used for reinforcing concrete roads, bridges, and tunnels. Its strength and durability ensure that these critical structures can withstand environmental stressors and heavy traffic loads.

3.2 Residential Projects

Wave iron wire is increasingly being adopted in residential construction, particularly for roofing, fencing, and decorative elements. Its flexibility allows for unique designs that can enhance the aesthetic value of homes.

3.3 Artistic Installations

Beyond functional applications, wave iron wire is also utilized in artistic installations. Artists and designers use it to create sculptures, decorative facades, and innovative landscaping features that transform public spaces.

4. Comparison with Traditional Steel Materials

When comparing wave iron wire to traditional steel materials, several factors come into play that highlight its advantages.

4.1 Cost-Effectiveness

While the initial cost of wave iron wire might be slightly higher than traditional options, its long-term benefits, including reduced maintenance and increased durability, make it a more cost-effective choice over time.

4.2 Performance Analysis

Wave iron wire outperforms traditional steel in several key metrics, including tension strength, flexibility, and resistance to fatigue. This performance advantage makes it a superior choice for modern construction needs.

5. The Manufacturing Process of Wave Iron Wire

Understanding the manufacturing process of wave iron wire reveals the intricacies involved in producing this innovative material.

5.1 Raw Material Selection

The quality of raw materials is crucial in the production of wave iron wire. High-grade steel is preferred to ensure the best performance characteristics, providing both strength and flexibility.

5.2 Production Techniques

The manufacturing process involves advanced techniques that create the wave patterns in the wire. These techniques not only enhance the material's properties but also ensure consistency in production, which is essential for maintaining quality standards.

6. Future Trends in Wave Iron Wire Usage

The future of wave iron wire in construction looks promising. As sustainability becomes increasingly important, wave iron wire's durability and recyclability position it as a preferred material for eco-friendly construction practices. Furthermore, its aesthetic properties are likely to drive innovative designs in architecture, making it a staple material in future urban developments.

7. Frequently Asked Questions

What is wave iron wire?

Wave iron wire is a type of steel wire with a unique undulated design that enhances its strength, flexibility, and aesthetic appeal.

Where is wave iron wire used?

Wave iron wire is used in various applications, including infrastructure projects, residential construction, and artistic installations.

How does wave iron wire compare to traditional steel?

Wave iron wire offers superior strength, flexibility, and aesthetic qualities compared to traditional steel materials, making it more suitable for modern construction needs.

Is wave iron wire cost-effective?

Although the initial cost may be higher, wave iron wire provides long-term savings due to its durability and reduced maintenance needs.

What are the benefits of using wave iron wire in construction?

The benefits include enhanced structural integrity, flexibility for various applications, aesthetic appeal, and long-term cost savings.

8. Conclusion

Wave iron wire is not just a material; it represents a shift in how we approach construction and design. Its unique properties offer unparalleled strength, flexibility, and aesthetic possibilities. As the construction industry continues to evolve, wave iron wire is poised to play a pivotal role in shaping the future of architecture and infrastructure. By incorporating wave iron wire into your projects, you can redefine structural possibilities and ensure that your construction endeavors stand the test of time.

Keywords:

Related news