What is the production process of galvanized wire?

Release Time:

Jan 10,2024

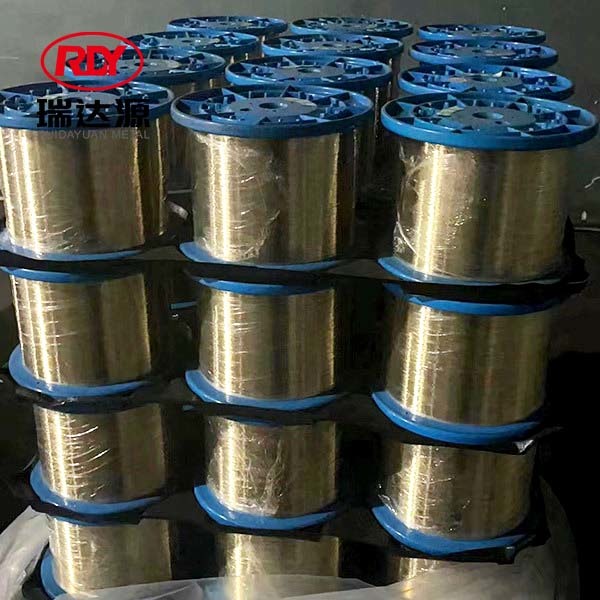

The production process of galvanized wire is one-stage drawing. We pull it through the mold, which is slightly smaller than the original diameter. In this way

The production process of galvanized wire is one-stage drawing. We pull it through the mold, which is slightly smaller than the original diameter. In this way, Z will eventually pull to the required length. It is not advisable to pull once. We have to number. The change from coarse to fine depends on the ductility of the metal. If the change is too big, it will hang up. After Z, the finished product is galvanized after drawing to a certain diameter. In this process, whenever the iron wire is pulled out, the friction high temperature will make the surface hard. So basically every time you pull it, you have to go into the stove and turn off the light. On the one hand, it is to reduce the hardness of the surface. On the other hand, during the wire drawing process, the surface has been deformed, but the center has not changed. So the internal stress is very large. Therefore, in order to eliminate internal stress, annealing must be relied on.

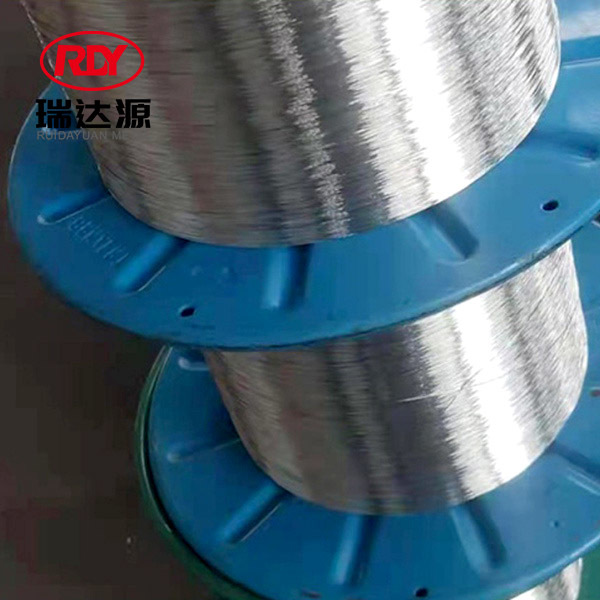

The iron wire can be softened again, and it can be refined again after the pressure is removed. However, we need to pay attention to the production of galvanizing line. First of all, remove all tools and piles that hinder activities in the workshop and equipment, and slowly put the iron wire into the tank during pickling to prevent acid from splashing on the body. When adding acid, slowly pour the acid into the water. Do not pour the water into the mountain. In order to prevent acid from splashing out, workers should wear protective glasses when working. Then the iron wire and other objects are being transported. It is strictly forbidden to push them violently. Pay attention to safety during operation, and others are not allowed to get on the train without permission. The shelves shall be placed gently and stacked firmly and neatly, and shall not exceed 5 boards. It is forbidden for human skin to contact acid and alkali directly.

Keywords:

Related news