Why Copper Coated Wire Is the Superior Choice for Electrical Wiring Projects

Release Time:

Sep 19,2025

Why Copper Coated Wire Is the Superior Choice for Electrical Wiring Projects Table of Contents Introduction to Copper Coated Wire Understanding Electrical Wiring: An Overview Advantages of Copper Coated Wire Comparative Analysis: Copper Coated vs. Traditional Wires Applications of Copper Coated Wire in Various Industries The Manufacturing Process of Copper Coated Wire

Why Copper Coated Wire Is the Superior Choice for Electrical Wiring Projects

Table of Contents

- Introduction to Copper Coated Wire

- Understanding Electrical Wiring: An Overview

- Advantages of Copper Coated Wire

- Comparative Analysis: Copper Coated vs. Traditional Wires

- Applications of Copper Coated Wire in Various Industries

- The Manufacturing Process of Copper Coated Wire

- Maintenance and Care for Copper Coated Wire

- Environmental Impact of Using Copper Coated Wire

- Conclusion: The Future of Electrical Wiring with Copper Coated Wire

- Frequently Asked Questions

Introduction to Copper Coated Wire

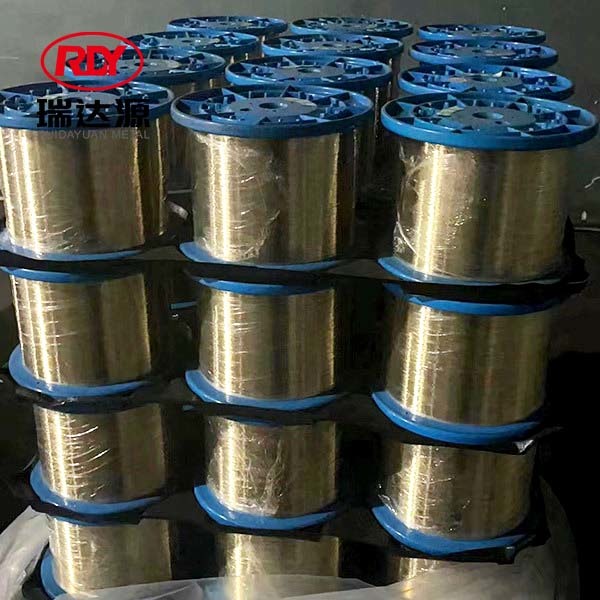

Copper coated wire is rapidly gaining recognition among electricians and engineers for its **superior performance** in electrical wiring projects. This innovative material combines the excellent conductivity of copper with the benefits of a more resilient substrate, providing a cost-effective solution for various applications. In this article, we will delve deep into the reasons why copper coated wire stands out as the preferred choice for both professional and DIY electrical projects.

Understanding Electrical Wiring: An Overview

Before exploring the advantages of copper coated wire, it's essential to understand the fundamentals of electrical wiring. Electrical wiring involves the installation and maintenance of electrical circuits that power homes, businesses, and industrial facilities. Wiring is typically made from conductive materials that allow electricity to flow efficiently. Traditional wiring options include pure copper, aluminum, and other alloys, each with its strengths and weaknesses.

The Role of Conductivity in Electrical Wiring

**Conductivity** is a critical factor in electrical wiring, as it directly impacts the efficiency and safety of electrical systems. Copper is renowned for its high conductivity, making it a top choice for electrical applications. However, pure copper can be prone to environmental factors that cause corrosion and degradation over time.

Advantages of Copper Coated Wire

Copper coated wire offers several advantages that enhance its usability in electrical wiring projects:

1. Enhanced Conductivity

Copper coated wire features a thin layer of copper over a core material, such as steel or aluminum, which provides excellent electrical conductivity. This structure ensures that the wire can carry current efficiently without significant energy loss.

2. Increased Durability

The inner core of copper coated wire adds strength and resilience to the overall design. This durability makes it suitable for applications in harsh environments where traditional copper wiring may fail due to bending or environmental exposure.

3. Cost-Effectiveness

Using copper coated wire can significantly reduce costs compared to pure copper wire. The lower material cost, combined with its durability and longevity, makes it an economically viable option for large-scale electrical projects.

4. Resistance to Corrosion

Copper coated wire is less susceptible to corrosion than pure copper wire. The protective layer of copper shields the inner core from moisture and environmental factors that contribute to rust and degradation.

5. Lightweight and Flexible

Copper coated wire is often lighter than traditional wiring options, making it easier to handle and install. Its flexibility allows for easier routing through tight spaces, streamlining the installation process.

Comparative Analysis: Copper Coated vs. Traditional Wires

To truly understand the benefits of copper coated wire, it’s essential to compare it with traditional wiring options like pure copper and aluminum wires.

1. Copper Wire vs. Copper Coated Wire

While pure copper wire offers excellent conductivity, it is also more expensive and less durable. In contrast, copper coated wire provides a balance of conductivity and cost, making it more accessible for various projects.

2. Aluminum Wire vs. Copper Coated Wire

Although aluminum wire is lighter and generally cheaper, it has lower conductivity and higher resistance. Copper coated wire outperforms aluminum in terms of both conductivity and durability, making it a superior choice for electrical applications.

3. Performance in High-Temperature Environments

Copper coated wire is designed to withstand high temperatures better than traditional wires, reducing the risk of overheating and electrical failures. This resilience makes it ideal for use in industrial settings where temperature fluctuations are common.

Applications of Copper Coated Wire in Various Industries

The versatility of copper coated wire extends across various industries, making it a favored option for numerous applications.

1. Electrical Appliances

Copper coated wire is commonly used in **electrical appliances**, including motors, transformers, and generators, where reliable conductivity is critical.

2. Telecommunications

In the telecommunications industry, copper coated wire is utilized for signal transmission due to its minimal electrical resistance and high-frequency performance.

3. Automotive Industry

Automotive manufacturers are increasingly adopting copper coated wire for wiring harnesses, where weight reduction and durability are paramount.

4. Renewable Energy Systems

Copper coated wire plays a significant role in renewable energy systems, including solar panels and wind turbines, where efficiency and longevity are essential.

5. Home Wiring and Renovations

For residential projects, copper coated wire is an excellent choice for home wiring due to its balance of performance and cost, making it ideal for both new constructions and renovations.

The Manufacturing Process of Copper Coated Wire

Understanding the manufacturing process of copper coated wire can provide insights into its quality and performance. The process involves several key steps:

1. Core Material Selection

The first step involves selecting a suitable core material, often steel or aluminum, known for its strength and lightweight properties.

2. Coating Application

The core is then coated with a thin layer of copper through processes like electroplating or drawing. This coating ensures that the wire retains the high conductivity associated with copper.

3. Quality Control Measures

Throughout the manufacturing process, stringent quality control measures are implemented to ensure that the wire meets industry standards for conductivity, strength, and durability.

Maintenance and Care for Copper Coated Wire

Maintaining copper coated wire is straightforward, ensuring its longevity and reliability in electrical projects.

1. Regular Inspections

Conducting regular inspections of wiring installations can identify signs of wear or damage early, preventing potential electrical failures.

2. Proper Installation Practices

Using proper installation techniques, such as avoiding excessive bending or tension, can extend the life of copper coated wire.

3. Cleaning and Protection

Keeping the wire clean and free from contaminants can help maintain its conductivity and overall performance.

Environmental Impact of Using Copper Coated Wire

Choosing copper coated wire can have a positive environmental impact through reduced resource consumption and waste.

1. Reduced Resource Use

Utilizing copper coated wire lessens the demand for pure copper, contributing to more sustainable resource management.

2. Recyclability

Copper coated wire is recyclable, allowing it to be repurposed at the end of its life cycle, further minimizing environmental impact.

3. Lower Energy Consumption

The enhanced efficiency of copper coated wire reduces energy consumption in electrical systems, leading to lower carbon footprints.

Conclusion: The Future of Electrical Wiring with Copper Coated Wire

In conclusion, copper coated wire emerges as the superior choice for electrical wiring projects, offering unmatched benefits in conductivity, durability, and cost-effectiveness. Its versatility across various applications and industries underscores its potential to revolutionize wiring standards. As technology continues to evolve, embracing copper coated wire will pave the way for more efficient, sustainable, and high-performance electrical systems.

Frequently Asked Questions

1. What is copper coated wire made of?

Copper coated wire consists of a core material, typically steel or aluminum, that is coated with a layer of copper to enhance conductivity and durability.

2. Why is copper coated wire preferred over aluminum wire?

Copper coated wire offers superior conductivity, durability, and resistance to corrosion compared to aluminum wire, making it a better choice for most electrical applications.

3. Can copper coated wire be used for high-temperature applications?

Yes, copper coated wire is designed to withstand high temperatures, making it suitable for applications in industrial settings and other environments with temperature fluctuations.

4. Is copper coated wire recyclable?

Yes, copper coated wire is recyclable, allowing for environmentally responsible disposal and resource management.

5. How do I maintain copper coated wire?

Regular inspections, proper installation techniques, and keeping the wire clean can help maintain its performance and longevity in electrical projects.

Keywords:

Related news