Understanding Galvanized Iron Wire: A Versatile Material for Construction

Release Time:

Sep 12,2025

Galvanized iron wire is a type of wire that has been coated with a layer of zinc to protect it from corrosion and rust. This process, known as galvanization, enhances the wire's durability, making it an ideal choice for various construction and decoration applications. The unique properties of galvanized iron wire contribute to its growing popularity in the building materials industry. One of the

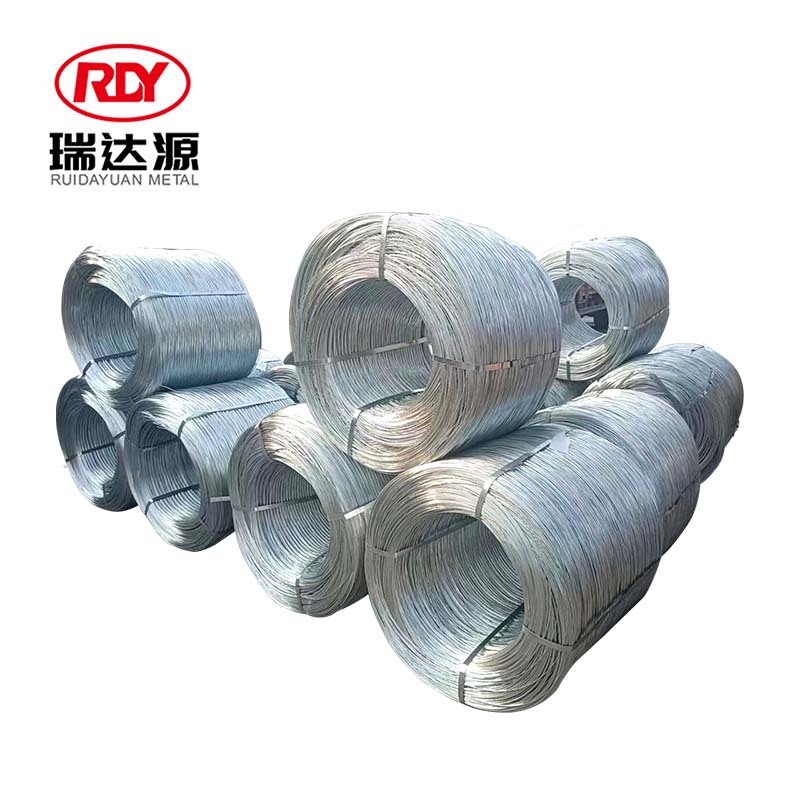

Galvanized iron wire is a type of wire that has been coated with a layer of zinc to protect it from corrosion and rust. This process, known as galvanization, enhances the wire's durability, making it an ideal choice for various construction and decoration applications. The unique properties of galvanized iron wire contribute to its growing popularity in the building materials industry.

One of the primary benefits of galvanized iron wire is its resistance to corrosion. The zinc coating acts as a barrier, preventing moisture from reaching the underlying iron, which is susceptible to rusting. This characteristic is particularly important in environments where the wire may be exposed to harsh weather conditions or moisture, such as in outdoor fencing, roofing, and reinforcement applications. As a result, galvanized iron wire has a much longer lifespan compared to non-galvanized alternatives.

In addition to its corrosion resistance, galvanized iron wire is known for its strength and versatility. It possesses high tensile strength, making it suitable for applications that require a sturdy material, such as load-bearing structures and support systems. This wire can be easily bent, twisted, or shaped to meet specific project requirements, offering flexibility for various construction needs. Whether used for tying rebar, creating mesh for concrete reinforcement, or crafting outdoor décor, galvanized iron wire proves to be a reliable solution.

Moreover, galvanized iron wire is available in various gauges, allowing builders and designers to select the appropriate thickness for their projects. Thicker gauges are ideal for heavy-duty applications, while thinner gauges work well for lighter tasks such as crafting and decorative purposes. This wide range of options ensures that there is a suitable type of galvanized iron wire for nearly every construction project.

Another significant advantage of using galvanized iron wire is its cost-effectiveness. While the initial investment might be slightly higher than that of non-galvanized wire, the long-term savings on maintenance and replacement costs make it a more economical choice over time. The durability and low maintenance requirements of galvanized iron wire contribute to its appeal, especially for large-scale construction projects where budget considerations are crucial.

In conclusion, galvanized iron wire is an indispensable material in the construction and decoration industry. Its corrosion resistance, strength, versatility, and cost-effectiveness make it an excellent choice for a wide range of applications. By understanding the benefits and properties of galvanized iron wire, builders and designers can make informed decisions that enhance the quality and longevity of their projects. Whether you’re involved in residential or commercial construction, this versatile wire is sure to meet your needs effectively.

One of the primary benefits of galvanized iron wire is its resistance to corrosion. The zinc coating acts as a barrier, preventing moisture from reaching the underlying iron, which is susceptible to rusting. This characteristic is particularly important in environments where the wire may be exposed to harsh weather conditions or moisture, such as in outdoor fencing, roofing, and reinforcement applications. As a result, galvanized iron wire has a much longer lifespan compared to non-galvanized alternatives.

In addition to its corrosion resistance, galvanized iron wire is known for its strength and versatility. It possesses high tensile strength, making it suitable for applications that require a sturdy material, such as load-bearing structures and support systems. This wire can be easily bent, twisted, or shaped to meet specific project requirements, offering flexibility for various construction needs. Whether used for tying rebar, creating mesh for concrete reinforcement, or crafting outdoor décor, galvanized iron wire proves to be a reliable solution.

Moreover, galvanized iron wire is available in various gauges, allowing builders and designers to select the appropriate thickness for their projects. Thicker gauges are ideal for heavy-duty applications, while thinner gauges work well for lighter tasks such as crafting and decorative purposes. This wide range of options ensures that there is a suitable type of galvanized iron wire for nearly every construction project.

Another significant advantage of using galvanized iron wire is its cost-effectiveness. While the initial investment might be slightly higher than that of non-galvanized wire, the long-term savings on maintenance and replacement costs make it a more economical choice over time. The durability and low maintenance requirements of galvanized iron wire contribute to its appeal, especially for large-scale construction projects where budget considerations are crucial.

In conclusion, galvanized iron wire is an indispensable material in the construction and decoration industry. Its corrosion resistance, strength, versatility, and cost-effectiveness make it an excellent choice for a wide range of applications. By understanding the benefits and properties of galvanized iron wire, builders and designers can make informed decisions that enhance the quality and longevity of their projects. Whether you’re involved in residential or commercial construction, this versatile wire is sure to meet your needs effectively.

Keywords:

Related news