Unveiling the Secrets of Galvanized Steel Wire for Stronger Foundations

Release Time:

Aug 22,2025

Unveiling the Secrets of Galvanized Steel Wire for Stronger Foundations Building strong, reliable foundations is crucial in construction, and one of the unsung heroes of this process is **galvanized steel wire**. This article will explore the advantages of using galvanized steel wire, its applications, and essential maintenance tips to ensure longevity. We will delve into its characteristics, bene

Unveiling the Secrets of Galvanized Steel Wire for Stronger Foundations

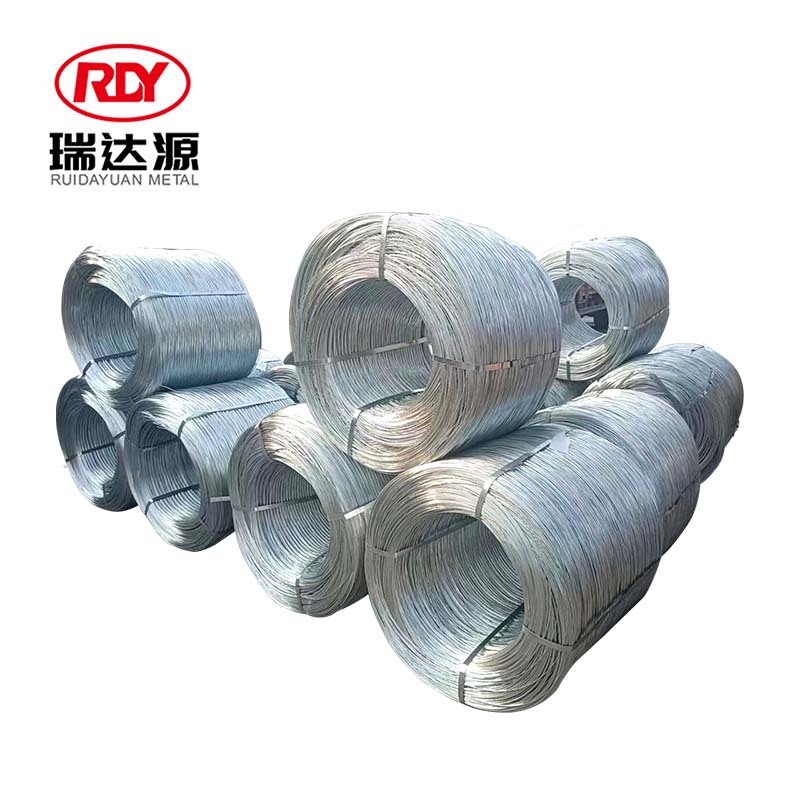

Building strong, reliable foundations is crucial in construction, and one of the unsung heroes of this process is **galvanized steel wire**. This article will explore the advantages of using galvanized steel wire, its applications, and essential maintenance tips to ensure longevity. We will delve into its characteristics, benefits, and how it can significantly enhance the quality of your construction projects.

Understanding Galvanized Steel Wire

Galvanized steel wire is produced by coating steel wire with a layer of zinc, which protects the steel from corrosion. The galvanization process involves either hot-dipping or electroplating. This added layer of protection is vital for construction applications, where exposure to moisture and other corrosive elements is common.

The Galvanization Process Explained

The **galvanization process** can be broken down into two main methods:

1. **Hot-Dip Galvanization:** In this method, steel wire is immersed in molten zinc, creating a thick and durable coating. This method provides a robust defense against corrosion.

2. **Electro-Galvanization:** This involves applying a zinc coating through electrolysis. Although this method offers a thinner coating compared to hot-dip galvanization, it provides an adequate level of protection for less demanding applications.

The Benefits of Using Galvanized Steel Wire

Utilizing galvanized steel wire in construction offers numerous benefits, making it a preferred choice for builders and contractors.

1. Superior Corrosion Resistance

One of the most significant advantages of **galvanized steel wire** is its exceptional resistance to rust and corrosion. The zinc coating acts as a barrier, preventing moisture from reaching the steel beneath. This characteristic is particularly important in environments exposed to harsh weather conditions.

2. Enhanced Strength and Durability

Galvanized steel wire is known for its high tensile strength. The process of galvanization ensures that the wire maintains its integrity even under heavy loads or during extreme weather conditions, providing a reliable option for construction projects.

3. Cost-Effectiveness

Though the initial cost of galvanized steel wire may be higher than non-galvanized options, the longevity and reduced maintenance costs associated with its use generally offset the initial investment. This makes it a cost-effective solution in the long run.

4. Versatility in Applications

From reinforcing concrete to fencing and wire rope applications, galvanized steel wire is versatile. Its strength and resistance to the elements make it suitable for a wide range of construction tasks.

5. Environmental Considerations

Using galvanized steel wire can also be seen as an environmentally friendly choice. Zinc is a naturally occurring element, and the recycling of steel products is well-established, making galvanized steel wire a sustainable building material.

Applications of Galvanized Steel Wire in Construction

The applications of galvanized steel wire extend far beyond basic uses in construction. Here are some prevalent applications:

1. Foundation Reinforcement

In foundation work, galvanized steel wire is often used in the form of wire mesh or rebar. It enhances the structural integrity of concrete, preventing cracks and ensuring longevity.

2. Fencing Solutions

Galvanized steel wire is a popular choice for fencing because of its durability and resistance to rust. Whether it’s for residential or commercial properties, it provides a cost-effective solution for security and privacy.

3. Wire Ropes and Rigging

In construction sites, **galvanized steel wire ropes** are crucial for lifting and rigging. Their strength and resistance to wear make them ideal for heavy-duty applications.

4. Support for Landscaping and Garden Projects

Galvanized steel wire is frequently used in landscaping for support structures, such as trellises and fences, ensuring stability in various outdoor projects.

5. Electrical Applications

In some cases, galvanized steel wire is used in electrical applications, including grounding and support for electrical conduits.

Maintenance Tips for Galvanized Steel Wire

While galvanized steel wire is designed to be durable, proper maintenance can further extend its lifespan.

1. Regular Inspections

Conducting regular inspections is essential to identify any signs of wear or damage. Look for areas where the coating may be compromised.

2. Cleaning to Remove Corrosive Elements

Cleaning the wire periodically helps remove any corrosive elements such as salt or chemicals that may cause deterioration. Use a mild detergent and a soft brush to avoid scratching the surface.

3. Touch-Up Coating

If any sections of the galvanized coating are damaged, consider applying a zinc-rich paint to protect those areas from corrosion.

4. Avoiding Physical Damage

Be mindful during installation and handling to avoid bending or kinking the wire, which could damage the protective coating.

FAQs About Galvanized Steel Wire

1. What is the lifespan of galvanized steel wire?

The lifespan of galvanized steel wire can vary based on environmental factors, but it typically lasts between 20 to 50 years, depending on the coating thickness and exposure conditions.

2. Can galvanized steel wire be used in coastal areas?

Yes, galvanized steel wire is suitable for coastal areas, but it may require more frequent inspections and maintenance due to higher humidity and salt exposure.

3. How does galvanized steel wire compare to stainless steel wire?

While both types are corrosion-resistant, stainless steel wire generally offers higher resistance to rust and corrosion but at a higher cost. Galvanized steel wire is more cost-effective for most applications.

4. Is galvanized steel wire safe for use in food applications?

Galvanized steel wire is not recommended for direct contact with food due to potential zinc leaching. It should be used in applications where food contact is not an issue.

5. Can galvanized steel wire be welded?

Yes, galvanized steel wire can be welded, but it requires special techniques and precautions due to the zinc coating, which can produce harmful fumes when heated.

Conclusion

Galvanized steel wire plays a pivotal role in constructing strong foundations and enhancing the durability of various structures. Its corrosion resistance, strength, versatility, and cost-effectiveness make it a vital component in modern construction. By understanding the benefits and applications of galvanized steel wire, builders and contractors can make informed decisions that lead to more robust and long-lasting foundations. Proper maintenance and care will further extend the life of this essential material, ensuring that your construction projects not only meet but exceed expectations.

Keywords:

Related news