Empowering Structures: The Structural Integrity of Copper Coated Iron Wire

Release Time:

May 16,2025

Empowering Structures: The Structural Integrity of Copper Coated Iron Wire Table of Contents 1. Introduction to Copper Coated Iron Wire 2. Key Benefits of Copper Coated Iron Wire 3. Applications of Copper Coated Iron Wire in Construction 4. Understanding the Structural Integrity of Copper Coated Iron Wire 5. Enhanced Corrosion Resistance in Harsh Environments 6. The Role o

Empowering Structures: The Structural Integrity of Copper Coated Iron Wire

Table of Contents

- 1. Introduction to Copper Coated Iron Wire

- 2. Key Benefits of Copper Coated Iron Wire

- 3. Applications of Copper Coated Iron Wire in Construction

- 4. Understanding the Structural Integrity of Copper Coated Iron Wire

- 5. Enhanced Corrosion Resistance in Harsh Environments

- 6. The Role of Copper in Electrical Conductivity

- 7. Installation Techniques for Optimal Performance

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Copper Coated Iron Wire

Copper coated iron wire represents a significant advancement in the field of construction and decorative materials. By combining the strength of iron with the superior properties of copper, this innovative material offers a unique solution for various structural needs. This article explores the remarkable benefits and applications of copper coated iron wire, emphasizing its role in enhancing structural integrity and performance.

2. Key Benefits of Copper Coated Iron Wire

Copper coated iron wire provides a multitude of benefits that make it an ideal choice for construction and decorative projects:

2.1 Superior Strength and Durability

The inherent strength of iron, coupled with the protective copper coating, results in a wire that is exceptionally strong and resistant to deformation under heavy loads. This strength ensures that structures can withstand significant stress over time.

2.2 Corrosion Resistance

The copper coating acts as a barrier against environmental elements, significantly reducing the risk of corrosion. This feature is particularly beneficial in areas exposed to moisture or harsh weather conditions, prolonging the lifespan of the wire and the structures it supports.

2.3 Enhanced Conductivity

Copper is renowned for its excellent electrical conductivity. The copper coating on iron wire enhances its performance in applications where electrical conductivity is crucial, such as in grounding systems and electrical installations.

2.4 Aesthetic Appeal

In addition to its functional benefits, the copper finish provides an attractive appearance, making copper coated iron wire suitable for decorative applications. Its unique color and sheen can enhance the visual appeal of any project.

3. Applications of Copper Coated Iron Wire in Construction

Copper coated iron wire has a wide range of applications in the construction industry, including:

3.1 Reinforcement in Concrete Structures

In concrete construction, copper coated iron wire is often used as reinforcement. Its strength enhances the structural integrity of concrete beams and slabs, helping to prevent cracking and failure.

3.2 Fencing and Security Solutions

The durability and corrosion resistance of copper coated iron wire make it an excellent choice for fencing. It provides secure boundaries for properties while maintaining a visually pleasing appearance.

3.3 Electrical Wiring and Grounding

The exceptional conductivity of copper allows this wire to be used in electrical applications, including wiring systems and grounding solutions. Its resistance to corrosion ensures reliable performance over time.

3.4 Decorative Features

Architects and designers are increasingly utilizing copper coated iron wire in decorative elements, such as railings, sculptures, and garden features. The wire's aesthetic properties add a touch of elegance to various designs.

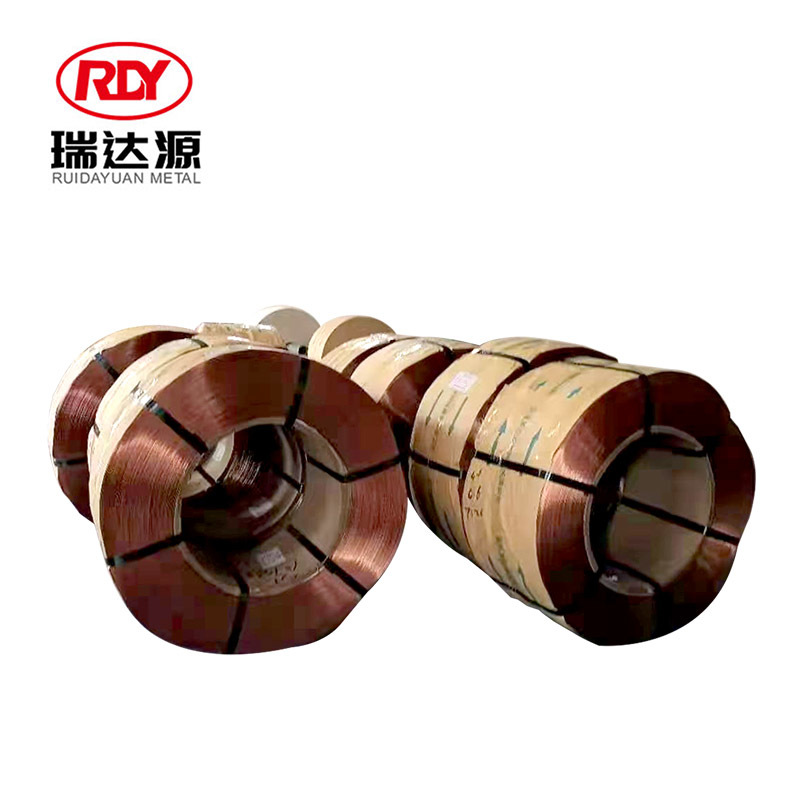

4. Understanding the Structural Integrity of Copper Coated Iron Wire

The structural integrity of copper coated iron wire is a critical factor in its effectiveness as a building material. This integrity is influenced by several factors:

4.1 Material Composition

Copper coated iron wire consists of a core made from high-quality iron, which provides strength, while the copper coating offers protection against environmental damage. This combination results in a wire that maintains its structural integrity under various conditions.

4.2 Manufacturing Process

The manufacturing process used for copper coated iron wire plays a significant role in its performance. High-quality production techniques ensure a uniform coating that adheres well to the iron core, maximizing the wire's strength and corrosion resistance.

4.3 Load-Bearing Capacity

Copper coated iron wire is designed to bear significant loads without compromising structural integrity. This capacity is crucial for applications that require the wire to support heavy materials or withstand substantial forces.

5. Enhanced Corrosion Resistance in Harsh Environments

Corrosion resistance is one of the standout features of copper coated iron wire. This characteristic is essential for ensuring the longevity of structures in challenging environments.

5.1 Mechanisms of Corrosion Prevention

The copper coating acts as a sacrificial layer, protecting the iron core from rust and degradation. In environments with high humidity or exposure to chemicals, this protective layer helps maintain the wire's integrity.

5.2 Applications in Coastal and Industrial Areas

Copper coated iron wire is particularly valuable in coastal regions where saltwater exposure can accelerate corrosion. Similarly, in industrial settings, where chemicals may be present, the corrosion-resistant properties of copper coated wire help ensure long-lasting performance.

6. The Role of Copper in Electrical Conductivity

The role of copper in enhancing electrical conductivity cannot be overstated.

6.1 Electrical Applications and Grounding

In electrical applications, copper coated iron wire is often used for grounding systems, ensuring that electrical currents safely travel to the ground. This application is critical for preventing electrical hazards and ensuring system reliability.

6.2 Efficiency in Power Transmission

The exceptional conductivity of copper allows for efficient power transmission, making copper coated iron wire an ideal choice for electrical wiring in both residential and commercial settings.

7. Installation Techniques for Optimal Performance

Proper installation of copper coated iron wire is essential for maximizing its benefits.

7.1 Preparation and Planning

Before installation, thorough planning is necessary. Assessing the project requirements and determining the appropriate wire gauge and length will ensure optimal performance.

7.2 Techniques for Handling and Installation

When handling copper coated iron wire, it is crucial to avoid bending or twisting the wire excessively, as this can compromise its structural integrity. Utilizing appropriate tools and techniques during installation will help maintain the wire's strength and performance.

8. Frequently Asked Questions (FAQs)

8.1 What is copper coated iron wire used for?

Copper coated iron wire is used in various applications, including reinforcement in concrete structures, fencing, electrical wiring, and decorative features.

8.2 How does the copper coating enhance corrosion resistance?

The copper coating acts as a barrier, protecting the iron core from exposure to moisture and chemicals that can cause rust and degradation.

8.3 Is copper coated iron wire suitable for outdoor use?

Yes, copper coated iron wire is highly suitable for outdoor use due to its corrosion-resistant properties, making it ideal for fencing and structural applications exposed to the elements.

8.4 Can copper coated iron wire be used in electrical applications?

Absolutely. The excellent conductivity of copper makes copper coated iron wire ideal for electrical applications, including grounding systems.

8.5 What is the load-bearing capacity of copper coated iron wire?

The load-bearing capacity can vary based on the wire's gauge and specific application. However, copper coated iron wire is designed to handle significant loads without compromising structural integrity.

9. Conclusion

Copper coated iron wire stands as a revolutionary material in the construction and decorative industries, providing unmatched strength, durability, and aesthetic appeal. Its ability to resist corrosion and enhance electrical conductivity makes it a versatile choice for various applications. By understanding its properties and benefits, we can harness the power of copper coated iron wire to empower structures, ensuring they remain robust, reliable, and visually appealing for years to come. Embracing this innovative material is a step forward in creating sustainable and enduring architectural solutions.

Keywords:

Related news