Contact Us

Tel:

+86-13851950711

E-mail:

sales@wirefactory.cn

Address:

No. 16 Huide Road, Shuangtang High-end Metal Products Industrial Park, Jinghai District, Tianjin

Steel wires for the prestressing of concrete

- Commodity name: Steel wires for the prestressing of concrete

- Description

-

Steel wires for prestressed concrete main implementation of national standards GB/T5223-2014.strand Executive GB/T5224-2003 standard,American standard ASMA416,ASTMA421,British Standard BS5896,Japanese Standard JlSG3536,international standards IS06934,the European standard EN10138 or consultation by the two sides agreed to supply the technology, the following main specifications for the products and technical parameters.

This product is mainly used for prestressde and post-tensioning tech-nology in big,medium and small sized of various shapes of PC structures,and widely used for civil engineering construction of large scale railroad,high-way bridges,buildings trusses,overhead crane besms industrial and civil prefabricated concrete floor,wall board,tubular piles,powers and nuclear power station,etc.

Steel wire with plane surface size and Tolerance each meter reference quality《GB/T5223-2014》

Nominal diameter

dn/mmDiameter allowable deviation

/mmNominal cross-sectional area

Sn/mm²Reference mass per meter

/(g/m)3.00 ±0.04 7.07 55.5 4.00 12.57 98.6 5.00 ±0.05 19.63 154 6.00 28.27 222 6.25 30.68 241 7.00 38.48 302 8.00 ±0.06 50.26 394 9.00 63.62 499 10.00 78.54 616 12.00 113.1 888 PC Steel wire with spiral ribs size and Tolerance《GB/T5223-2014》

Nominal diameter

dn/mmSpiral rib

Quantity/pieceBase circle size Outer wheel profile dimensions Single auxiliary size Spiral rib lead

C/mmBase diameter

D1/mmAllowable deviation

/mmOuter contour diameter

D/mmAllowable deviation

/mmwidth

a/mm4.00 4 3.85 ±0.05 4.25 ±0.05 0.90-4.30 24-30 4.80 4 4.60 5.10 1.30-1.70 28-36 5.00 4 4.80 5.30 6.00 4 5.80 6.30 1.60-2.00 30-38 6.25 4 6.00 7.70 30-40 7.00 4 6.73 7.46 ±0.10 1.80-2.20 35-45 8.00 4 7.75 8.45 2.00-2.40 40-50 9.00 4 8.75 9.45 2.10-2.70 42-52 10.00 4 9.75 10.45 2.50-3.00 45-58 Elimination of stress-ray circular and spiral rib steel mechanical properties《GB/T5223--2014》

Nominal diameter

dn/mmtensile strength

σb/MPa

Not less thanNon proportional regulation

Elongation stress

σp0.2/MPa

Not less thanTotal under maximum force

elongation

(Lo=200mm)Bending frequency/

(Times/180 °)

Not less thanbending radius

R/mmThe initial stress is equivalent to the percentage of the nominal tensile strength,% After 1000 hoursStress relaxation rater1%

Not greater thanWLR WNR WLR WNR 3.00 1470

1570

1670

1770

18601290

1380

1470

1560

16401250

1330

1410

1500

15803.5 3 10 60

70

801.0

2.0

4.54.5

8

124.00 4 15 5.00 6.00 1470

1570

1670

17701290

1380

1470

15601250

1330

1410

15004 15 6.25 4 20 7.00 4 20 8.00 1470

15701290

13801250

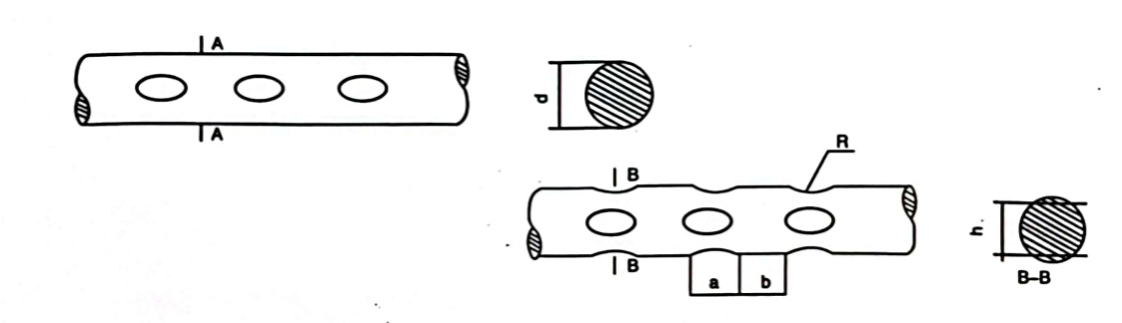

13304 20 9.00 4 25 10.00 1470 1290 1250 4 25 12.00 4 30 Shape and size of two sides indented P.C.wire

d h a b R Nominal

diameterTolerance Nominal

sizeTolerance Nominal

sizeTolerance Nominal

sizeTolerance Nominal

sizeTolerance 5.00 ±0.05 4.60 ±0.50 3.50 ±0.50 3.50 ±0.50 3.50 ±0.50 7.00 6.60 GB/T 5223-2003

Type

Nominal

Diameter

mmNomina

Area

mm ²Nomina

Tensile

Strength

Not less than

MPaMin.Strength

at 0.2% Non-

proportiona

Extension

Not less than MPaElongation

ar Max.Load

(L0=200mm)

No less thanPerverse bend

L0≥500mmRelaxation WLR WNR Bend

Times

Not less than

(Times/180 °)Bend

Radius

mmnitial

Load

Nomina

Tensile

Strength1000h Value

no more thanWLR WNR Smooth

indented

helica

rib

4.00 12.57 1470

1570

1670

1770

18601290

1380

1470

1560

16401250

1330

1410

1500

15803.5% 3 10 60%

70%

80%1.0%

2.5%

4.54.5%

8%

12%4.80 18.10 4 15 5.00 19.63 6.00 28.27 1470

1570

1670

17701290

1380

1470

15601250

1330

1410

15006.25 30.68 20 7.00 38.48 8.00 50.26 1470

15701290

13801250

13309.00 63.62 25 10.00 78.54 1470 1290 1250 12.0 113.1 30 AS 1310-1987

Type Nominal

Diameter

mmTolerange

mmRange of

Tensile

Strength

Not less thanMPaMin

Strength at

0.2%Non-

proportional

Extension

Not less thanMPaMin

Elongation

after fracture

L0=250mmPerverse bend

L≥500mm

Relaxation Min Max Bend

Times

Not less than

(Times/180 °)Bend

Radius

mmInitial

Strength

Nominal

Min

Tensile

Strength1000h Value

no more thanNormal Low Cold

drawn

wire2.0 ±0.025 2000

18502250

210075% Min.

Tensile

Strength1.5% ****** ****** ****** ****** ****** 2.5 Round

wire and

indented

wire3.0 ±0.005 1700

1850

1700

1550

1700

1550

1620

17001950

2100

1950

18000

1950

1800

1870

195085% Min.

Tenslle

Strength2.5% All the

wire 3

times

without

fracture10 70%

80%6.5%

8.5%2.0%

3.0%3.0 10 4.0 3.5% 10 5.0 15 5.0 15 7.0 20 7.0 20 7.0 20 8.0 ±0,075 1450

15501700

180025 8.0 25 ASTM A421-1998

Nominal

DiameterMin

Tenslle Strength

MPaMin.Strength at 1%Extenslon

Not less than MPaMin.

Elongation

L₀=250mmRelaxation in mm Type

BA

MPaType

WA

MPaType

BA

MPaType

WA

MPaInitial Strength

Nominal Min

Tensile Strength1000h Value

no more than

Normal0.192 4.88 - 1725 - 1465 4.0% 70%

80%2.5%

3.5%0.196 4.98 1655 1725 1407 1465 0.250 6.35 1655 1655 1407 1407 0.276 7.01 1620 1620 1377 1377 BS 5896-1980

Nominal

Diameter

mmNominal

Tensile

Strengt

MPaNominal

Area

mm²Min.

Breaking

Load

kNLoad

at 1%

Elongation

kNMin.

Elongation

at Max

Load

L0.200mmDuctility Test Relaxation Reverse Bends Initial

Load

Actual

Breaking

Load1000h Value

No more thanBends Times

Not less than (times/180 °)Bend Radius

mmRelax

Class

1Relax

Class

27

71570

167038.5 60.4

64.351.3

54.33.5% 4 times for

smooth

wires

3 times for

indented

wires20 60%

70%

80%4.5%

8%

1251.0%

2.5%

4.5%6

61670

177028.3 47.3

50.140.2

42.615 5 5 1670

177019.6 32.7

34.721.8

29.515 4.5 1620 15.9 25.8 21.9 15 4

41670

167012.6 21.3

22.317.9

19.010 JIS G 3536-1994

Type Nominal

Diameter

mmDiameter

Tolerance

mmMin.

Breaking

Load

kNMin.Load at 0.2%

Non-proportional

Extension

kNMin.Elongation

L₀-100mm

%Relaxation Initial Load

Nominal

Breaking Load1000h Value no

more thanNormal Low SWPR1AN

SWPR1AL

SWPD1N

SWPD1L2.9 ±0.03 12.7 11.3 3.5 70% 8.0% 2.5% 4 ±0.04 21.1 18.60 5 ±0.05 31.9 27.90 4.0 6 44.1 38.70 7 58.3 51.00 4.5 8 ±0.06 74.0 64.20 9 90.2 78.00 SWPR1BN 5 ±0.05 33.8 29.90 4.0 7 62.3 54.90 4.5 8 ±0.06 78.9 69.10 PC WIRE-Low Relaxation

STANDARD Gade

(Mpe)Diameter (mm) Nomi

nal

Area

(mm²)Weight (kgk) Breaking Load

(min)

(kN)Yield Load (min)(kN) Indented

Deph

(mm)Elogatio

n(%)Reverse Bend

(times)Staightness

mm.Relaxation at 1000 Hr.(%mm)

lnitial Load (%)Norminal Dia Nomind Tolerince 0.1% 0.2% 0.3% 60 70 80 JIS G3536-1999 SWPDIL

Deformed

SWPRILR

ound4.00

5.00

6.00

7.00

8.00

9.00±0.04 12.57 98.7 21.1 18.6 ≥3.5

≥4.0

≥4.0

≥4.5≤2.5 II ±0.05 9.64 154.0 31.9 27.9 ±0.05 28.27 222.0 44.1 38.7 ±0.05 38.48 302.0 58.3 51.0 ±0.05 50.27 395.0 74.0 64.2 ≥4.5 ±0.06 63.62 499.0 90.2 78.0 ≥4.5 BS5896-1980 1770 4.00 ±0.04 12.6 98.9 ±2.0 22.3 18.5 19.0 0.07-0.17 ≥3.5 4 for Plain

wig.3 for

Indented wireNot exceed

30 mm,Over

lmgth 1 m≤1.0

(A)≤2.5 II ≤4.5 II 1670 4.00 40.04 12.6 98.9 ±2.0 21.0 17.5 17.9 0.07-0.17 1620 4.50 ±0.05 15.9 125.0 ±2.7 25.8 21.4 21.9 0.07-0.17 1860 5.00 ±40.05 19.6 154.0 ±3.1 36.5 30.3 31.0 0.07-0.17 1770 5.00 ±40.05 19.6 154.0 ±3.1 34.7 28.8 29.5 0.07-0.17 1670 5.00 ±10.05 19.6 154.0 ±3.1 32.7 27.2 21.8 0.07-0.17 1770 6.00 ±0.05 28.3 222.0 ±3.7 50.1 41.6 42.6 0.10-0.20 1670 6.00 ±40.05 28.3 222.0 ±3.7 47.3 39.3 40.2 0.10-0.20 1670 7.00 ±40.05 38.5 302.0 ±4.3 64.3 53.4 54.7 0.10-0.20 1570 7.00 ±0.05 38.5 302.0 ±4.3 60.4 50.1 51.3 0.10-0.20 AS/NZS 4672-

20071770 4.00 12.6 98.9 ±2.0 22.3 18.5 19.0 ≥3.5 4 for Plain

wire.3 for

Indented wireNot exceed

25 mm,Over

length 1 m≤3.0 II 1770 5.00 19.6 154.0 ±3.1 34.7 28.8 29.5 1670 5.00 9.6 154.0 ±3.1 32.7 27.2 27.8 670 6.00 28.3 222.0 ±3.7 47.3 39.3 40.2 670 7.00 38.5 302.0 ±4.3 64.3 50.1 51.3 1570 8.00 50.3 395.0 ±5.9 79.0 65.6 67.1 470 9.00 63.6 499.0 ±7,2 93.5 74.8 76.7 EN10138-2004 Y1860C 4.00 12.6 98.4 ±2.0 23.4 20.8 0.06-0.13

0.06-0.13

0.06-0.13≥3.5 4 for Plain

wire.3 for

ndented wireNot exceed

25 mm,Over

lngth 1 m≤4.5 I W1770C 4.00 12.6 98.4 ±2.0 22.3 19.6 Y1770C 5.00 19.6 153.1 ±3.1 34.7 30.5 Y1670C 5.00 19.6 153.1 ±3.1 32.7 28.8 0.06-0.13 Y1770C 6.00 28.3 221.0 ±4.4 50.1 44.1 0.09-0.16 Y1670C 6.00 28.3 221.0 ±4.4 47.3 41.6 0.09-0.16

0.09-0.16

0.09-0.16Y1670C 7.00 38.5 300.7 ±6.0 64.3 56.6 Y1570C 7.00 38.5 300.7 ±6.0 60.4 53.2 ASTM A421-

2005WA 4.98 ±0.0

519.48 152.9 33.60 28.54 ≥4.0 Not exceed 3

nch,Over

length 60

inch≤3.5 II 6.35 31.67 248.6 52.41 44.56 7.01 38.59 302.9 62.52 53.14 BA 4.98 19.48 152.9 32.24 27.41

44.56

53.146.35 31.67 248.6 52.41 7.01 38.59 302.9 62.52 1=%OF ACTUAL BREAKING LOAD II-%OF MINIMUM BREAKING LOAD

Steel wire stands as a cornerstone of modern engineering, embodying strength, resilience, and adaptability in its very essence. In this concise exploration, we uncover the distinctive features of steel wire, underscoring its diverse applications and indispensable role across various industries.

At its core, steel wire is forged from high-grade steel alloys, meticulously crafted to deliver unparalleled tensile strength and durability. Its robust construction enables it to withstand immense loads and forces, making it an indispensable component in structural frameworks, mechanical assemblies, and industrial machinery.

One of the hallmark traits of steel wire is its exceptional flexibility despite its formidable strength. This unique characteristic allows it to be seamlessly integrated into intricate designs and complex configurations, facilitating seamless installation and optimal performance in diverse environments.

Moreover, steel wire's corrosion-resistant properties make it exceptionally well-suited for outdoor applications, where exposure to moisture, chemicals, and harsh weather conditions is unavoidable. Its protective coating ensures long-term durability, safeguarding against rust and degradation even in the most demanding environments.

In the realm of construction, steel wire serves as a versatile building material, employed in an array of applications ranging from reinforcing concrete structures to suspending overhead cables and erecting fences. Its high tensile strength and malleability allow for precise shaping and positioning, enabling architects and engineers to realize their vision with confidence.

In the automotive industry, steel wire plays a crucial role in the fabrication of wire harnesses, springs, and other components essential for vehicle performance and safety. Its resilience and conductivity ensure reliable electrical connections, while its ability to withstand vibrations and mechanical stress enhances overall durability and longevity.

Furthermore, steel wire finds extensive utility in the manufacturing sector, where it is used in the production of industrial machinery, tools, and equipment. Its strength and versatility make it an indispensable resource for fabricating conveyor belts, lifting cables, and precision components, driving efficiency and productivity in manufacturing processes.

Beyond its industrial applications, steel wire serves as a creative medium for artists and craftsmen, who harness its inherent properties to sculpt intricate sculptures, jewelry, and decorative accents. Its ability to be shaped, bent, and formed with precision allows for the realization of intricate designs and imaginative creations.

In summary, steel wire emerges as a quintessential building block of modern engineering, embodying strength, flexibility, and durability in equal measure. From towering skyscrapers to intricate artworks, its versatility and reliability continue to shape the landscape of innovation and creativity, serving as a testament to human ingenuity and perseverance.

Key words:

Zinc-coated wire | Galvanized Wire | Spool Wire | Barbed Wire | Steel strand

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!