Contact Us

Tel:

+86-13851950711

E-mail:

sales@wirefactory.cn

Address:

No. 16 Huide Road, Shuangtang High-end Metal Products Industrial Park, Jinghai District, Tianjin

Steel Strand

- Commodity name: Steel Strand

- Description

-

Product Introduction

Prestressed concrete with steel wire, steel wire is mainhimplemented national standards GB/T5224, GB/T5223, United States standard ASTMA416. ASTMA421British standard BS5896, JlSG3536, 1S0934, international standard KSD, South Korea standard EN101387002, European standard , Malaysian Standard MS1138:PART4:2007, Australian/New Zealand StandardAS/NZS4672or the agreed technical agreement, the following are the main specifications and technicalparameters.

一、Prestressed Concrete Steel Strand

The product is mainly used as auxiliary reinforcing strand for concrete structure.e.g.long spanned bridge'son railway and highway,overhead crane construction,multi-floor industrial building and etc,Products havebeen widely applied to the major domestic rail, road, and construction.

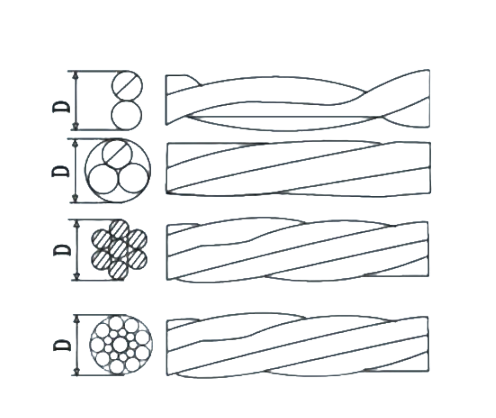

Prestressed Concrete Steel Strand

SpecificationName

Dor.Dia(mm)

Shape

Prestressed Concrete Steel Strand Series

1x2 P.C.Strand

6.0;8.0;10.0

12.0;14.0

1x3 P.C.Strand

6.45;8.60;

10.75;12.90;15.051x7 P.C.Strand

(Normal or L ow relaxation)9.0:12.0;12.7

15.0:15.20;15.24

15.70;1 7.80

18.90;21.601 x9S P.C.Stand

21.8;28.6

TechnicalSpecificatior

1x7 Steel strand's size and allowable deviation, nominal cross-sectional area, theoretical weight per meter

Steel strandstructure Nominal Dia Dn/mm Djameter Tolerance /mm Strand Nominal cross-sectional area So/mm2 Theoretical weight per meter/(g/m) Range(extened)/%of core wire's diameternot less than 1X7 9.50

(9.53)+0.30

-0.1554.8 430 2.5 11.10

(11.11)74.2 582 12.70 +0.40

-0.1598.7 775 15.20

(15.24)140 1101 15.70 150 1178 17.80

(17.78)191

(189.7)1500 18.90 220 1727 21.60 285 2237 1X71 12.70 +0.40

-0.1598.7 775 15.20

(15.24)140 1101 (1X7)C 12.70 +0.40

-0.15112 890 15.20

(15.24)165 1295 1800 223 1750 Note: Supply can be made according to the specifications in parentheses 1 x 19 Steel strand's size and allowable deviation, nominal cross-sectional area, theoretical weight per meter

Steel strand structure Nominal Dia Dn/mm Diameter Tolerance /mm Strand Nominal cross-sectional area So/mm2 Theoretical weight per meter/(g/m Range(extened)/%of core wire's diameternot less than 1X19S

(1+9+9)21.8 +0.40

-0.15313 2482 28.6 532 4229 1 x 2 Steel strand's size and allowable deviation, nominal cross-sectional area, theoretical weight per mete

Steel strand structure Nominal Dia Dn/mm Diameter Tolerance/mm Cross section area Sn/mm² Re.mass per meter/(g/m) Steel strand diameter Dn/mm Wire Dia d/mm 1×2 5.00 2.50 +0.15

-0.059.82 77.1 5.80 2.90 13.2 104 8.00 4.00 +0.25

-0.1025.1 197 10.00 5.00 39.3 309 12.00 6.00 56.5 444 1 x 3 Steel strand's size and allowable deviation, nominal cross-sectional area, theoretical weight per mete

Steel strand structure Nominal Dia Dn/mm Steel strand measurement A /mm Measurement A Tolerance /mm Cross section area Sn/mm² Re.mass per meter /(g/m) Steel strand diameter Dn/mm Wire Dia d/mm 1×3 6.20 2.90 5.41 +0.15

-0.0519.8 155 6.50 3.00 5.60 21.2 166 8.60 4.00 7.46 +0.20

-0.1037.7 296 8.74 4.05 7.56 38.6 303 10.80 5.00 9.33 58.9 462 12.90 6.00 11.20 84.8 666 1×3l 8.70 4.04 7.54 38.5 302 1 x7 Mechanical properties of structural steel strand

Structure Norminal dia. Dn/mm Tensile strength(Rm/MPa) Strand entire root most vigorously Fm/kN≥ The most vigorous of the maximum whole root strand Fm,max/kN≤ 0.2%Yield strength Fp0.2/kN≥ Elogation at max load Not less than Agt/%≥ Stress relaxation ability The initial load is eq-uivalent to the perc-entage of actua maximum force 1000h stress relaxation rater/%≤ 1X7 9.50

(9.53)1860 102 113 89.8 All specifications

3.5

All specifications

70

80All specifications

2.5

4.511.10

(11.11)138 153 121 12.70 184 203 162 15.20

(15.24)260 288 229 15.70 279 309 246 17.80

(17.78)355 391 311 18.90 409 453 360 21.60 530 587 466 9.50

(9.53)1960 107 118 94.2 11.10

(11.11)145 160 128 12.70 193 213 170 15.20

(15.24)274 302 241 18.90 1820 400 444 352 15.70 1770 266 296 234 21.60 504 561 444 1X7I 12.70 1860 184 203 162 15.20

(15.24)260 288 229 (1X7)C 12.70 1860 208 231 183 15.20

(15.24)1820 300 333 264 18.00 1720 384 428 338

1x19 Mechanical properties of structural steel strand

Structure Norminal dia.Dn/mm Tensile strength(Rm/MPa) Strand entire root most vigorously Fm/kN≥ The most vigorous of the maximum whole root strand Fm,max/kN≤ 0.2%Yield strength Fp0.2/kN≥ Elogation at max load Not less than Agt/%≥

Stress relaxation ability The initial load is eq-uivalent to the perc-entage of actual maximum force 1000h stress relaxation rater/%≤ 1X19S

(1×19+9)21.8 1860 583 645 513 3.5 70

802.5

4.528.6 990 1096 854 1 applicable to mining support × The relaxation rate of steel strands for 19 structures is not required. 1 x2 Mechanical properties of structural steel strand

Structure Norminal dia.Dn/mm Tensile strength(Rm/MPa) Strand entire root most vigorously Fm/kN The most vigorous of the maximum whole root strand Fm,max/kN 0.2%Yield strength Fp0.2/kN≥ Elogation at max load Not less than Agt/%≥ Stress relaxation ability The initial load is eq-uivalent to the perc-entage of actual maximum force 1000h stress relaxation rater/%≤ 1X2 5.00 1720 16.9 18.9 14.9

All specifications

3.5

All specifications

70

80

All specifications

2.5

4.55.80 22.7 25.3 20.0 8.00 43.2 48.2 38.0 10.00 67.6 75.5 59.5 12.00 97.2 108 85.5 5.00 1860 18.3 20.2 16.1 5.80 24.6 27.2 21.6 8.00 46.7 51.7 41.1 10.00 73.1 81.0 64.3 12.00 105 116 92.5 1 x 3 Mechanical properties of structural steel strand

Structure Norminal dia. Dn/mm Tensile strength(Rm/MPa) Strand entire root most vigorously Fm/kN≥ The most vigorous of the maximum whole root strang Fm,max/kN≤ 0.2%Yield strength Fp0.2/kN≥ Elogation at max load Not less than Agt/%≥ Stress relaxation ability The initial load is eq-uivalent to the perc-entage of actual maximum force 1000h stress relaxation rater/%≤ 1X3 6.20 1720 34.1 38.0 30.0 All specifications

3.5

All specifications

70

80All specifications

2.5

4.56.50 36.5 40.7 32.1 8.60 64.8 72.4 57.0 10.80 101 113 88.9 12.90 146 163 128 6.20 1860 36.8 40.8 32.4 6.50 39.4 43.7 34.7 8.60 70.1 77.7 61.7 8.74 71.8 79.5 63.2 10.80 110 121 96.8 12.90 158 175 139 Mechanics properties of steel strand-KSD7002

Strand type Nominal diameter(mm) Tolerance(mm) Area of sectionr(mm²) Re.mass per meter(g/m) Tensile strength not less than(Rm/MPa ) Breaking force(Fm/kN) Non proportiona extension not less than(Fp0.2/kN) Elongation not less than(Agt/%) Stress relaxation ability Tne initial load is equivalent to the perc-entage of nominal maximum force The relaxation at 1000h

not more thanSWPC7BN

SWPC7BL9.50 +0.40

-0.2054.84 432 1860 102 86.8

All specifications

3.5%

AIl specifications

60%

70%

80%

AIl specifications

1.0%

2.5%

4.5%11.10 74.19 580 138 118 12.70 98.71 774 183 156 15.20 138.7 1101 261 222 Mechanics properties of steel strand-ASTMA416

Grade Nominal dia(mm) Tolerance(mm) Cross section area (So/mm²) Be.mass per 1000m

(Kg/1000m)Minimum Breaking

loadMin Load at 1% Extension(KN) Lo≥610mm(%) The relaxation at 1000h (Initial load to 70% of nominal max load)(r/%) Not more than Low-Relaxation Nomal-Relaxation 250

[1725]9.53 ±0.40 5161 405 89.0 80.1 3.5 2.5 3.5 11.11 69.68 548 120.1 108.1 12.70 92.90 730 160.1 144.1 15.24 139.35 1094 240.2. 216.2 270

[1860]9.53 +0.65

-0.155484 432 102.3 92.1 11.11 74.19 582 137.9 124.1 12.70 98.71 775 183.7 165.1 15.24 140.00 1102 260.7 234.6 British Standard-BS5896

Strand type Nominal diameter(mm) Tolerance(mm)

Area ofsectionr(mm²) Theoretical Weight per 1000 metre(kg) Tensile Strength Specified characte-ristic breaking Load Specified characte-ristic 0.1% yielding Load Load at 1% Elongation

Lo≥500mmMinimun Elongation

at MAX loadRelaxation Value 1000h 60%

Initial Load70%

Initial Load80%

Initial LoadStandard 7-wire 9.3 +0.3 52 408 1770 92 78 81 3.5 1.0 2.5 4.5 -0.15 11 -0.3 71 557 1770 125 106 110 3.5 1.0 2.5 4.5 -0.15 12.5 +0.4 93 730 1770 164 139 144 3.5 1.0 2.5 4.5 -0.2 15.2 +0.4 139 1090 1670 232 197 204 3.5 1.0 2.5 4.5 -0.2 Super 7-wire 9.6 +0.3 55 432 1860 102 87 90 3.5 1.0 2.5 4.5 -0.15 11.3 -0.3 75 590 1860 139 118 122 3.5 1.0 2.5 4.5 -0.15 12.9 +0.4 100 785 1860 186 158 163 3.5 1.0 2.5 4.5 -0.2 15.7 +0.4 150 1180 1770 265 225 233 3.5 1.0 2.5 4.5 -0.2 Die-drawn 7-wire 12.7 +0.4 112 890 1860 209 178 184 3.5 1.0 2.5 4.5 -0.2 15.2 +0.4 165 1295 1820 300 255 264 3.5 1.0 2.5 4.5 -0.2 18 +0.4 223 1750 1700 380 323 334 3.5 1.0 2.5 4.5 -0.2 Japanese Standard-JISG3536

Steelgrade Nominal diameter(mm) Tolerance(mm) Area of sectionr(mm²) Theoretical Weight per 1000 metre(kg) Breaking Load(≥KN) Load at 0.2% Permanent elongation(≥KN) Minimum elongation at Max Load≥(%) Relaxation Value≤(%) SWPR7A 9.3 51.61 405 88.8 75.5 3.5 2.5 10.8 69.68 546 120 102 3.5 2.5 12.4 92.901 729 160 136 3.5 2.5 15.2 38.70 1101 240 204 3.5 2.5 SWPR7B 9.5 5484 432 102 86.8 3.5 2.5 11.1 74.19 580 138 118 3.5 2.5 12.7 98.71 774 183 156 3.5 2.5 15.2 138.70 1101 261 222 3.5 2.5 Australian Standard (AS/NZS 4672)

Strand type Nominal Diameter(mm) Area of sectionr

(mm²)Theoretical Weight per 1000 metre

Tensile Strength Minimum breaking force(KN) Specified charactenstic 0.1% yielding load Specified characteristic 0.1 % yielding load Minimum elongation at Max Load≥(%) Relaxation value 1000h Nominal Value(kg) Tolerance% 70%

Initial Load80%

Initial Load7-wire

ordinary9.3 51.6 405 +4/-2 1720 88.8 72.8 75.4 3.5 2.5 3.5 9.5 55.0 432 1850 102 83.6 86.6 11.1 73.9 580 1870 138 113 117 12.4 92.9 729 1720 160 131 136 12.7 98.6 774 1870 184 151 156 12.9 100 785 1840 186 158 165 15.2 140 1101 1790 250 205 212 15.2 140 1101 1860 261 214 222 18.0 190 1492 1780 338 277 287 18.0 190 1492 1850 353 289 300 Malaysian Standard (MS1138: PART4)

Strand type Nominal Diameter(mm) Area of sectionr

(mm²)Theoretical Weight per 1000 metre Tensile Strength Minimum breaking

force(KN)Specified charactenstic 0.1 % yielding load Specified characteristic

0.1% yielding loadMinimum elongation at Max Load≥(%) Relaxation value 1000h Nominal Value(kg) Tolerance% 70%

Initial Load80%

Initial Load7-wire

ordinary9.5 54.8 432 +4/-2 1860 102 83.6 86.6 3.5 2.5 4.5 12.7 98.7 774 1860 184 151 156 15.2 139 1101 1860 259 212 220 Steel strand wire stands as a testament to the remarkable fusion of strength, flexibility, and durability, making it an indispensable material across various industries. This concise exploration delves into the distinctive characteristics of steel strand wire, highlighting its versatility and wide-ranging applications in engineering, construction, telecommunications, and beyond.

At its core, steel strand wire is crafted from high-quality steel, meticulously engineered to deliver exceptional tensile strength and resilience. Its composition undergoes rigorous manufacturing processes, resulting in a product that boasts superior load-bearing capabilities, making it ideal for applications requiring robust structural support.

One of the key features of steel strand wire is its remarkable flexibility despite its inherent strength. This attribute enables it to be effortlessly shaped and manipulated, allowing for versatile usage in an array of construction projects. Whether reinforcing concrete structures, erecting suspension bridges, or securing slopes in civil engineering projects, steel strand wire offers unmatched adaptability to meet diverse design requirements.

Moreover, steel strand wire's corrosion-resistant properties make it well-suited for outdoor applications, where exposure to environmental elements is unavoidable. From coastal regions to harsh industrial environments, its protective coating ensures long-term durability, safeguarding structures against degradation and minimizing maintenance costs over time.

In the realm of telecommunications, steel strand wire plays a pivotal role in the deployment of aerial cables for telecommunication networks. Its high tensile strength and minimal elongation characteristics make it an ideal choice for supporting cables over long spans, ensuring reliable signal transmission even in challenging terrain.

Furthermore, steel strand wire finds extensive utility in the field of agriculture, particularly in vineyard trellising and orchard support systems. Its robust construction provides sturdy support for growing crops, while its flexibility allows for natural movement, promoting healthy plant growth and maximizing yields.

Beyond its industrial applications, steel strand wire serves as a foundational element in the creation of artistic installations and sculptures. Its malleability enables artists to fashion intricate shapes and forms, while its enduring strength ensures structural integrity, resulting in captivating works of art that stand the test of time.

In summary, steel strand wire epitomizes the harmonious blend of strength, flexibility, and longevity, making it an indispensable asset in various industries and creative endeavors. Whether fortifying infrastructure, enhancing telecommunications networks, or cultivating agricultural landscapes, its versatility and reliability continue to redefine the possibilities of modern engineering and innovation.

Key words:

Zinc-coated wire | Galvanized Wire | Spool Wire | Barbed Wire | Steel strand

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!